- About the Dynohub pictured and its magnetism and efficiency.

- Electronics to improve the light output such as LED lighting.

- Dynohub repair, making a magnet keeper, re-magnetising theory and practical suggestions, {in this section I have not been able to re-magnetise a dynohub for certain}

- Newer and older 3 and 4-speed AW and FW variable gear hub lubrication and maintenance,

- Lighting circuits and regulator circuits,

- Motors that can be used as generators.

- Addendum; Alternative LED lighting circuits that can be made from salvaged parts,

- Addendum; Bicycle bottle generator experiments using a stepper motor salvaged from a printer,

- Blog; Electronics project that can take more power at higher bike speed with good efficiency when required for battery charging and powering other devices. Using a configured or learnt strategy or controlled by the cyclist.

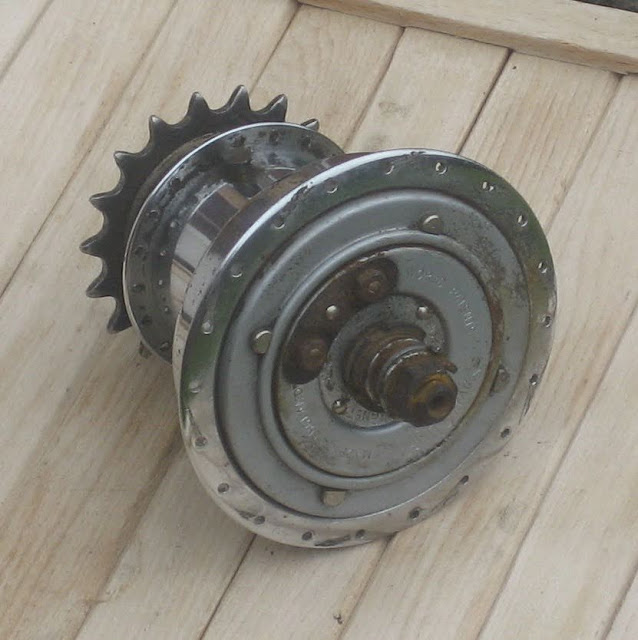

The Dynohub pictured above;

- Bearing friction which is very small in this case of a thin oiled bearing.

- Magnetising force - the power needed to change the magnetism polarity (north to south, south to north) in the iron conducting the magnetism to the winding this is very small and might be 1% of the power available. That is the available power generated and the magnetising power used increases with frequency. This can be determined by looking at the B-H curve for the mu-metal.

- Eddy currents in the iron conduct the changing magnetism this depends on how thinly it is laminate. GH6 bike Dynohub's has three ply laminations there are three laminations compared to a transformer, or a motor which has many laminations. I have read an anecdote of someone getting one or two hundred volts from a Dynohub by taking it off a bike and spinning it fast, which suggests that eddy current losses did not limit the output voltage at high frequencies and probably are not a significant issue. That Dynohub produced 100 or 200Vac.

- Copper losses are the losses due to the resistance of the winding (which is 5 ohms) when current is drawn is a significant factor, though not discernible by the cyclist; I2R which is; 0.45W = 0.32 x 5 in this case.

- This power loss is significant 25% at rated power 1.8W.

- A different effect is observed and said on social media: a Dynohub which on small wheel bicycle's turns faster than cycling a full-size bike, and tends to burn out filament lamps, that is the output current increases with speed.

- A filament lamp's current self regulates a little when supplied from a voltage source such as a battery by comparison. But the power tends to run away when supplied by a variable current source. For example a quartz halogen filament lamp's cold resistance is about 1/20th of its hot resistance.

- A vintage GH6, 8 or 12 Dynohub are less efficient because the magnet is lower-powered but a Dynohub uses more copper and iron in compensation but losses are still be higher.

- A modern hub generators losses are more than 10% of the available power when not connected but varies between makers of modern generators. These are magnetising and eddy current losses. The path of the alternating magnetism seems unnecessarily long. See Skjegg blog link below for measurements carried out on some modern hub generators.

- See the addendum with pictures of motors at the bottom of this page for more efficient designs.

- But the losses are a lot higher in a modern hub generator system (up to 45%). See Skjegg blog link below for measurements carried out on some modern hub generators. The electronics waste power instead of using more sophistication to just take the power required.

- The amount of power wasted in a modern hub generator additional system may be 7W compared to 2-3W below or 1W. That is if I have understood the two blogs correctly.

Voltage regulator;

LED lighting;

Dynohub maintenance

- BSA and others - many sizes not known.

- Sturmey-Archer;

- GH12 (1937 - 44), 111 mm outside diameter (from pictures). 12V, 2.7 W, and 3 W,

- GH8 (1939 - 44), 90 mm OD (from pictures), 8 V, 1.2 W,

- GH6 (1944 - 83) Dynohub, AG and FG variable gear Dynohub. 6 V, 2 W (reduced to 1.8 W subsequently).

- The estimated magnet internal diameter measuring inside the bolts is; 70mm. and width 24 mm,

- The length required of mu-metal required is the circumference; 210 mm = pi.D.

- Therefore ensure there is at least 230 x 30 mm mu-metal.

Picture - Making the keeper; Find something of about the right diameter, (glass jar wrapped it in a rage), and then bend the mu-metal around the protected jar. The kitchen scissors are described as cut anything up to tin plate steel and are more suitable than the tin snips on the right. A hammer, anvil (use a vice with care), and a file to clean up the cut edges.

- Put grease in the labyrinth's grove around the bearing to form a water seal, I have put the grease in the nut but not in the bearing side yet.

- Hold the shaft still in a vice lightly but firmly on the flat sides of the shaft, set the slack in the bearing by tightening the cone-nut finger tight then loosen 1/2 turn. Then tighten the locknut whilst holding the cone-nut still with the thin spanner.

- A thin spanner is need to hold the thin inner nut whilst the outer lock nut is tightened.

- There is a Sturmey-Archer grease that can be obtained from SJS cycles.

- Millers semi-fluid EP bearing grease is the correct product for hubs after 1989. It is identical to the Sturmey-Archer product but a lot cheaper.

- Castrol Spheerol L/EP0 is also a thinner grease that is suitable.

|

| Do not use 3-in-one oil in a gear hub it leaves a black residue that stops the hub working eventually. |

|

| Hardly used heavy 1955 Raleigh with a new condition FG, 4 speed, Dyno-four and selector. |

- 1950 FW the wheel turned freely and three of the four gears worked there is a fault in the hub, cable and trigger design but the hub had been properly oiled with thin oil regularly when in use since new more than 25 years earlier. This hub had been oiled for its first 25 years with the wrong oil, 3-in-one, that had caused a fault after 30 years or so of a lot of use but the hub was otherwise clean inside.

- As if the hub were designed for a stiffer cable run. The cable is very tight in Bottom gear both the cable where it had rusted on the pulley wheel and the indicator rod have broken in the past. Evidently the cable had required progressively more tension as the deposit from the 3 in one oil deposit built up.

Originally the Normal gear clicked no doubt had been set that way to bring the selector positions closer together in the lighter cable tension higher gears? My father said it was a shame because Normal is the best gear, which I agree it is being the lightest most efficient speed to pedal when it is most noticeable when you want to relax at the top of a hill or on the near flat.The sheath end filed flat

- The hub gear and selector are a 1950 made but unusually like a 1946 version the hub is a stainless steel type. The clicking was resolved when the hub was maintained in about 2019, some pawl springs were replaced but the worn pawls and right cup which no doubt had similar wear as the pawls were kept as they were within tolerance. I understand a lighter spring was also fitted because the original was heavy. The hub, selector and the rear wheel rim, look like they have been replaced in 1950 under guarantee? The hub gear is considerably better than it had been and worked properly for a short time then reverts 3 of speeds working. Quickly the new cable deteriorated to become no better than the previous replacement.

The cable sheath is a square section spiral so it is not compressible and a second replacement of 2024 is the same. I do not know recall what the cable sheath from 1950 was like but it was good and the cable was plastic covered. Drop handlebars on my bike cause the cable routing to be very curvy. Significantly the cable shape changes as the cable tension changes but the either pieces of tape shown made all four speeds work briefly in other words gear selection is still unreliable.The sheath end filed flat

- The trigger is not worn enough to explain the issue and the notches are

precise, not worn to radiuses. Four-speed

triggers are often replaced but I have not done that. But I have

damaged it a bit as a teenager but now have to squeeze the side back together

with a vice successfully.

Tape minimise cable movement helped briefly

- It turns out that the section of cable with an outer sheath should be no more than 18" this forms tight curves on my drop-handlebar bike. I am not convinced that this was necessary but I have reduced the cable sheath length by 10". I have also recently changed the outer sheath again (2024) this made the gears work properly briefly. The bike shop did not know what a less springy type sheath recommended was and both sheaths look good tightly would square section wire?

- This issue with the cable shape changing at different speed selection does not arise with comparatively straight handle bars. But all FW variable gear hubs are said to be unreliable except when they are new. The new one on the 1955 Step-thru bike I have works very nicely, with good margin for mis-adjustment, (more than the FW on my Lenton pictured even when just set for B or just N gear but not both). The tape to the handlebars works well then it does not work.

Chose to set the cable to the indicator to get speeds 2,3,4. Or tighten the cable to get speeds 1,2,4. The much greater pull effort required to get bottom gear means that the cable assembly must not be too springy which is unavoidable where the radius are severe with drop handlebars. If a pannier bag carries much weight knocks the cable it will knock the hub out of N (3) gear. You may have just two good speeds 2 and 4. I have changed the rack and given the cable more clearance consequently and anyway the old new 1970s rack was welded steel which the joints kept fracturing on.

Tape minimise cable movement removed subsequently.

- The correct Sturmey-Archer cables outer sheath is smaller in diameter but thicker square section spiral than brake cable and has a strong plastic outer. The cut ends should be filed or ground flat.

- This has improved the function and I now have 4 speeds or 3 of 4 speeds and sometimes 4 speeds but the cable needs to be adjusted often. But the maintenance work carried out for me on the hub has made its function much better than it had been for a many decades plus the N gear does not click (not the freewheel tick) that had existed since the hub was new, and my father complained was a shame because it is the best gear. As this is a late, early-type FW or an early later type FW the click in N probably was, a back of a fag packet, work-around, an undocumented modification.

|

| Worn sprocket from my Lenton Sports the teeth have worn hook shaped. |

FG or FW gear hub - Another solution;

Modify the hub to use a second cable. I am advised improves the reliability of the hub and makes gear change easier is to convert it to a two cable, five-speed hub. I have not carried out this modification to the hub;

- No. 6 of a set of videos on the conversion If you don't have the suitable sun gear you will still have 4 speeds but with an easier cable pull but don't use the 5th, super-high gear;

- https://youtu.be/KJCPmj4I8CI Part 1 video (the early type FW before about 1950 should have the correct type sun gear, I believe),

- https://youtu.be/n3smEgvhf-M part 2 video,

- https://youtu.be/T96kiwY39i8 part 3 video,

- https://youtu.be/dwauZgc60os Part 4 video,

- https://youtu.be/cy7SdOjMFcE Part 5 video,

- https://youtu.be/HOTVluTo5cY Part 6 video explanation (also above),

- https://youtu.be/qNHM4mmXjMg Part 7 video changing the cogs,

- https://youtu.becChd-drYSmcc Part 8 video cables and levers on the bike.

- In conclusion, the FW is such a nice hub with gears spaced just right with N being the most efficient perfectly placed when you get to the top of a hill, level out, speed up and need a rest. Bottom gear is hard to get into though and on a hill by the time I have pulled the lever to B the bike may have stopped moving. The hub along with a very good sports frame and very low friction thin oil lubrication is worth keeping and running.

---------------------------------

- Conclusion variable gear hub maintenance;

- Some of these have more than one lubrication point.

- FM, FC, AM and AC are more complicated and have two epicyclic gear assemblies were developed in about 1939 to 1945.

- The four speed FW and FG wide spacing hubs are not so widely spaced were the last Raleigh Sturmey-Archer designed as a family owned business.

- The AW was developed in about 1935, but newer ones have a shorter pedal drop when changing gear and from the late 1980s is sealed with a very thin grease.

|

| FW broken Indicator rod and Toggle chain |

- GH 12 - I believe the circuit is two filament lamps in series rated at 250 mA. Short one lamp to see if the other lamp illuminates then short the other lamp this will determine if there is a simple lamp failure.

- GH 8 - I believe the circuit is two filament lamps in series rated at 150 mA. If the circuit is the same as the GH 12 then the test is the same.

- GH 6 - The circuit is two 6V filament lamps in parallel rated to add up to 280 mA or 300 mA for example 40 mA and 240 mA. If one lamp fails then the other lamp will be supplied with too much current and fail. Therefore, turn the wheel slowly at first to see if one or both lamps illuminate.

- All dyno-hub types operate silently but the freewheel and some gear hub should tick in some speeds.

- Turn the shaft and notice the Dynamo's detent force - which feels springy sort of lumpy and is very light. It does not matter which direction the wheel is rotated in. The magnet is magnetised.

- Short the dynamo output with a wire. Turn the shaft and notice the dynamo stronger magnet detent force - which feels springy lumpy but takes more effort. The magnet is magnetised and the windings are good so the dynamo is good

- If the force was no different as described the winding probably has a short circuit or the connection is open circuit.

- Check the continuity with a battery and a light bulb or a multimeter.

- If there was no detent force felt then the magnet is demagnetised.

It will be necessary to experiment to find out how much is just enough current so thereby minimise the risk of damaging the Dynohub?

- Another strategy, is to allow the poles to move so they are aligned then hold the shaft firmly so it does not move when the pulse of current arrives but the magnetic poles may swap polarity instead.

- Pulse the Dynohub twice so the dynamo has no cause to move again for the second pulse. This is the most promising strategy.

- Connect up as above and pulse the power on/off so that the poles align*.*

- Reverse the polarity of the power supply.

- Clamp the Dynohub stationery then power on/off.

- Un-clamp the Dynohub so that it can move freely then power on/off.

- If the magnet polarity had changed the dynamo should not move but it did move to a new alignment.

- I also tried with a 20V DC power supply unsuccessfully.

- Connected a 35VAC to the dynamo - this was not adequate and the dynamo remained magnetised but the magnetism was reduced. But the current would be quite low and the amount of demagnetisation expected would be modest.

- The current output but showed the current was reduced to; 380-400mA after the demagnetising experiment. Then re-magnetising and increased to 400-440mA subsequently.

- The keeper has been made long enough to be used on larger diameter GH8 or GH12 dynamos.

- Once the Dynohub was re-assembled the power output proved to be not compromised by having been disassembled and the keeper used.

- Testing the output voltage peaked at 30 Vac as before and the short circuit current varied between 370 mA to 420 mA slow to fast.

- The tapered fingers of the coil iron as the magnetic flux lessens would not be done to save materials cost. I can not see a voltage regulation strategy in this design. Any power saving would be trivial due to magnetising loss being reduced by using less iron.

|

| AL-0031-02C (2) High Voltage re-magnetising circuit. There is a risk that the coil will brake down and be of no use. The capacitor should be 400V or 450V and the diodes at least 600V e.g. 1N4005. |

- Power disconnected, The capacitor is discharged - The device to be magnetised is connected.

- Power is connected and the switch moved to Charge - check with a meter that the capacitor is charged.

- Switch is moved fire and check the capacitor is Fully discharged - then disconnect the power.

- Disconnect the device.

The device can then be checked that it has magnetised.

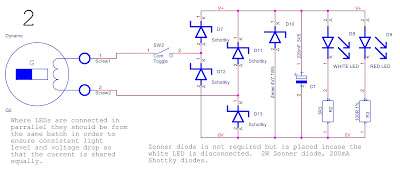

- Therefore half-wave rectifier circuits (1 above) and (3 below) but without capacitors will noticeably flicker at 15KPH (41Hz).

- The full-wave rectifier circuit (2 above) without the capacitors fitted may not noticeably flicker at 7KPH (41Hz). The time that the rectified AC cycle is not carrying current is much shorter.

- Assume that a GH6 hub will provide 6Vac 300 mA with a particularly strong magnet and close air gap, at 5RPM.

- No load output voltage due to winding resistance is; 1.5V = 5R * 300 mA therefore 7.5V

- At 300mA the peak current 420mA.

- Peak voltage; 10.5V = 1.4 * 7.5V , if this occurs no load at 5MPH (guess) then the maximum speed for <180V would be; 85MPH.

- <<80MPH or <<40MPH with a small wheel bike. These speeds or over voltage is unlikely to occur but the circuits include a Zener diode in case the dynamo is shorted than disconnected at peak current.

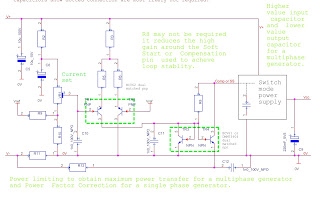

- IC Controllers are now obsolete; TCA-785 Infineon but old stock is available.

- A discrete solution using transistors works well. I have created a draft design using an MIC1555 timer IC rather than a unijunction transistor such as 2N6027 and 2N6028.

- The losses due to voltage drop are about 1.6V which is about; 500mW. So it is not efficient but it good enough to not take a noticeable amount of power. It does not take any power when the lights are turned of.

- The controller sheet AL-0056-03? further below used with this circuit also consumes some power.

- The Controller is simple, the MOSFET + 2x Schottky diodes drop is lower than the SCR alternatives further above.

- The controller is low speed which is okay because operating frequency is low so the switching losses should be modest.

- The

losses due to voltage drop could be; ~1.2V which is; ~350mW (300mA * 1.2V). But the MOSFET used is likely to have greater on resistance depending on the Dynohubs peak voltage. And could be less efficient unless a very high current or more sensitive gate part is used?

- At modest load the power supply turns off during part of the alternating current cycle and no power is wasted during that part of the cycle. Overall increased power wasted is progressively reduced.

These circuits are better than the simpler triac based regulator but are not very different to each other. This circuit could be made more efficient by reducing the maximum voltage to 100V. The lower voltage components would tend to have lower on voltage drop's thereby making the design more efficient.

It probably turns out that 150V maximum is a better option giving a bicycle speed of <60MPH.

Tony Hadland - How to repair old Sturmey-Archer hubs

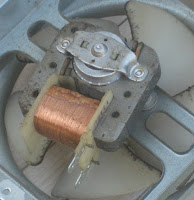

- 1970's Impex 350mA, 5V/winding (4), 48 step stepper motor. 8 wires.

- 1950s Induction motor (variable reluctance motor) - is not magnetised but will magnetise when connected to an AC power and spinning. The capacitor provides a phase-shifted supply and sets the motor direction. When spun a little faster than synchronising speed, this motor will become a generator and put power back into the supply.

If disconnected the motor stops generating power safely. But if capacitors are connected across the windings and the rotor has remnant magnetism some of these motors will build up magnetism and start to generate power when spinning.

This would not be suitable as a bicycle dynamo.

- Permanent magnet brush motor - will produce direct current if spun.

- 1980's Astrosyn stepper motor; 24-step, 16V, 80ohms (200mA)/winding (4) - this has a much more powerful magnet than the 1970s Impex motor and is a more powerful motor it is smaller.

- Central heating timer permanent magnet motor - this is like the dynamo in construction but turned inside out.

- Hard disk stepper motor 8 pole - this will also generate but the voltage is so low that it would have no use.

The motor is assembled then the magnet is magnetised by a pulse from a high voltage source. This type of construction is used from 24 up to 500 step hybrid stepper motors.

- The Dynohub should output up to 20V when the bike is ridden fast I understand. That is up to 7W.

- Manage battery charging.

- A tilt sensor is used to reduce the power taken from the dynamo using parameters set by the cyclist such as a tablet computer connected.

- Running, say, four times two strings anti-parallel of 7 + 4 LEDs in series. Total 88 LEDs, would be the most efficient option. {Picture above but with all blocks of LEDs fitted}.

- Full-wave rectifier with or without the centre tap running two 11 LEDs in series. Total 22 LEDs, uses less wiring and has redundancy. {Picture right but with all blocks of LEDs fitted}.

Experimental home-made bottle generator evaluation;

0' is; V=1.4*Vrms, I=1.4*Irms,45' is; V=Vrms, l=2*Irms.

There is no power factor correction and less than optimum power is taken between 0' 45' 90' 180' 270'. But with a simple reservoir capacitor would output <2/3rds of the possible power. Roughly calculating for 5V or 6V out, buck SMP ICs;

- L7987L st.com; 4.2W = 55V x 1.7 x 2 x 23mA,

- LMR36510 ti.com; 4.6W = 60V x 1.7 x 2 x 23mA

- LMR36506 ti.com; 3W at 5V out.

- MAX17793 up to 80V up to in, up to 3A 5V out

Single phase generator power transfer optimisation;

Vr1 sets the RMS current taken from the generator.