Changed; 07/03/2026 - 06/03/2026

DRAFT

- The remnant magnetism in the dynamo is required for it to start generating, but alternatively, the battery can be used instead. But in the conventional system, the dynamo also has to produce more than 5 times the power that the field requires to start generating. That is, the field is supplied with only ~20% of the dynamo's power. In contrast, this circuit can deliver nearly 100% of the dynamo's power at lower RPM to the field and thereby continue to operate at lower RPM.

- Conventionally, the dynamo needs to generate more than nothing, but some dynamos need a bit of revving to start if they haven't been used for some time. But setting a high charge and waiting longer should also work, unless it has an electronic regulator that requires a 1V or 2V threshold to be crossed before it starts. I have also included some transistorised control box circuits based on those likely to have been used in the 1970s; they have fewer electromagnetic Interference (EMI) protection and prevention measures than modern automotive electronics have.

- The second and subsequent circuits use all the power generated by the remnant magnetism in the dynamo initially to power the field, so it builds up to full generating power quickly and provides extra power sooner. The dynamo must produce at least 400mV to start up, or in the example with the relay, instead of an auxiliary boost regulator little more voltage than nothing is required. Web search tells me 2V for a 12V dynamo and consequently 1V for a 6V dynamo, at a modest RPM. At higher RPM, the circuit can operate in buck mode, reducing the dynamo's power waste and temperature rise.

- At higher RPM, the buck switch-mode circuit can deliver a lot more of the power normally recycled back to the dynamo for the car's electrics. I suggest current limits that increase in power for say 15 minutes, then reduce to 100%, 120%, 150%, 200% or the maximum available. The buck-boost circuit is likely to be more useful with pre-World War II cars. The maximum may be 25A, which is 30A less the Field winding current.

Expectation:

- Maximum power transfer. If the dynamo model were resistive, then it would deliver a maximum power transfer of 6.5A at 3.5V, boosted to 3.2A at 7V, which is 2A for the field winding and 2A for the coil supplied by the dynamo and the battery. Thereby reducing the battery drain to 1A.

- But if current limiting is the major factor. In this case, the voltage will still have dropped to 3.5V, but at a current of 13A. This can be boosted to 7V at 6.5A. That is 2A for the field, 2A for the ignition, and 2A or so for trickle charging or some auxiliary circuits, such as some of the lighting.

- By comparison, without the boost regulator, the output would be 7V at zero current, so there is no current for the field, so the dynamo could never generate 7V or sustain any lower voltage and consequent lower field current. That is, the dynamo could not start up at this low RPM.

- The likely outcome is that the dynamo will generate a combination of models (1) or (2), and the power output will spiral down to nearly nothing at lower RPM. Either way, there will not be enough power to run some of the car's electrical systems at low RPM.

At 2,400 RPM, the dynamo would deliver a maximum of 13A at 12V (over 14V). The buck regulator could deliver over 26A = 13A * 14V / 7V, less 2A for the field winding, leaving 24A. In this case, the average field current would be reduced so that less power circulates in the dynamo whilst delivering the same or more than the original electrical system would have.

At 3,600 RPM, the dynamo could deliver a maximum of 37A at 21V or run the armature at one-third current, which is 11% of the power or the field current reduced to protect the buck-boost regulator from overvoltage. The circuits include an overvoltage clamp protection, which produces shorting pulses to return the dynamo's current as motive force, reducing the torque taken from the engine.

The graph shows a small section of the dynamo power output. The upward diagonal lines shading region is the original power output, and the downward diagonal line region is the buck beneficial region. The areas to the left are the boost mode region. The solid region is the boost extra power region. The graph extends further to the right and has the potential to generate significantly more power. The electrical system should withstand higher current than originally would have, but for a short time, while the battery demands more current.

The first practical electric motors and generators were developed between 1832 and the 1880s. Two principles were demonstrated by Benjamin Franklin's electrostatic motor in 1748 and Michael Faraday's electromagnetic motor in 1821. Practical electrostatic motors are being developed and used now; they are low-speed, high-torque, higher efficiency, lower material cost, but are lower density than a conventional electromagnetic motor.

The mechanical cut-out was invented in 1915, web AI tells me.

Steam cars were very quiet; some were modest speed, others were very fast, but like petrol cars, they needed a lot of maintenance, although the starting was a bit safer than hand cranking an ICE.

Electric cars were the first powered vehicles to be turn-on-and-go.

Like most technology at the time, it would be very expensive.No rechargeable batteries vehicles at first but primary batteries, cables or rails

Electric vehicles mostly in USA

- The system is not accurate, and it has a lot of positive feedback, so when the dynamo voltage rises, the field winding voltage rises, and the dynamo would generate even more power when the electrical systems need less power. The battery plays an important part in stabilising the voltage, preventing the voltage from rising.

- The dynamos' iron may be sized so that the field winding saturates at, say, 6V, thereby limiting the dynamo's maximum output current, but the voltage would still increase as the engine speed increases, the field current setting and the battery prevent that. The current limiting I described is true of all dynamos and alternators; it is part of their magnetic design.

- The field winding fuse protects against voltage and power from running away at the lower current setting. In this case, a 1.5A fuse is probably about right, not the higher values I have found recommended on the internet.

- I have guessed the switch connection between D, F1 and F2. By comparison, Ford did not include a dynamo power setting switch before introducing the regulator, but the third brush was also used to change the dynamo power output for summer and winter use. Probably the best strategy is to always run an earlier Ford Model Y car with the headlights on, using the winter setting except when you need to fast charge the battery after starting the car.

- Voltage runaway could occur if the battery has become high impedance and so it is unable to regulate the voltage or accept much charging current. This occurs if the battery is worn out or the acid level has been allowed to drop too much. But I have also found that if the acid level drops and has been topped up with water, the battery's impedance becomes low, and its voltage is very low, until it is charged up. Note that distilled water does not mix with the acid easily, but floats on top, can freeze and crack the battery's casing in winter.

- The cut-out connects when the dynamo voltage is above the expected battery voltage, perhaps 8V, then that current flows into the electrical system, which will enhance the magnetism, keeping the cut-out connected.

- The cut-out disconnects when battery current flows back into the dynamo, combined with the battery voltage dropping.

|

| Austin Cars - guessing the switch's internal connection. There are two or three current rate settings. |

- Austin 7's later wiring diagram differs in the power setting for the side lights.

- When lights and a high charge rate are required, the side lights are evidently designed to be used instead of the headlights. Otherwise, the headlights should be used.

- Side lights are very dim and best only used when parked, as required on a fast road. That is, it is a bad but necessary compromise to drive on sidelights when the higher rate of charge is required. This option is not available on earlier cars.

- Earlier Austin 7s, other cars and makes, side lights use the medium current setting. A wire shown dotted is connected between the F1 terminals. So, there was no high charge rate when any lighting was switched on, and there was no power to spare anyway when the headlights were on.

- The driver monitors the ammeter and reduces the charge rate when the battery has recovered from starting the car, and the charge rate has died back. The electrical system has no protection if the charge rate is left set high for too long.

- The driver needs to move the charge rate switch according to the ammeter, and what inspecting the battery electrolyte tells him. Use a hydrometer, or if the battery needs topping up more often than once every two weeks, or if bubbles form after a long drive, you need to reduce the charging rate. But if there were just one bubble in each cell after a long drive, the charging is about right. [if I remember correctly]. It is necessary to adjust the third brush on the dynamo periodically.

- The manual says the ammeter reading should come down to +2A to +4A trickle charge, which is a necessary high rate to compensate for when the electrics are running on battery whilst idling. Therefore, a car, as I said, was only suitable for a hands-on person.

- The Austin 7 electrics total was up to 70W; the dynamo was rated at 6V, 11A, but most other models and makes were rated higher than this, and earlier Austin 7s may have had a lower dynamo rating. The battery was 50AH, probably 300A maximum? Austin car club say 300-400A was the initial current of the starter. This would be the short-circuit current of the battery, cables, and motor before the crank has movement. 100A, used to be said for starting, it could not be higher for maximum power transfer, allowing for battery wear, when cranking. The spark voltage was about 25,000V, but the Austin Manual says 6,000V, no doubt with the spark plug fitted.

- Web search tells me that after starting, the battery will demand 30-60A, which, is the limit of the cars electrical system. This is not fast charging but normal charging, in which cable and battery resistance can be compensated for, but in a small pre-war car the dynamo may deliver as little as 2A to 9A.

When I was very young, from 1959 to 1963, I was taken on holiday 250 miles a few times, to Devon and Cornwall, from Kent in an about 1935 Austin 7 and one or both Morris 8s. Mum complained that she had to keep kicking in the foot well of the passenger side to keep the electric fuel pump running on one of the Morris 8s. Later, we went further, but in bigger cars. My father also drove his Ford Anglia to Paris, a similar distance, with his mates. Most cars had worm and wheel, or worm and pin steering box; some had rack and pinion steering and less well-developed damping and suspension, though sport bicycles, of the time, had much better active damping due to their apparent tuning with the cyclist, regardless of his weight, but sensitivity to placement of weight on a cycle rack. Otherwise, the cars have a tendency to wander about on the road like the Austin 7 in this video. The ignition timing adjustment placed on the steering wheel was replaced by about 1930 with the centrifugal advance and vacuum advance mechanisms within the distributor. The second video features a much smarter car, a Riley, but it could be an MG or one of the less basic Morris or Austin cars.

The regulator and cut-out:

- Auxiliary equipment became more viable, and A valve car radio of the time may require 6V, 5A (guess), which is more than the ignition system, so by adding accessories, the electrical system current balance could easily be very wrong, particularly if the car's electrics did not include a regulator.

- Some cars were negative earth, while others were positive earth. A valve radio could probably cope with either, but other cars used 12V, and this type of radio would not accommodate different battery voltage cars. Heaters in the valves have different current ratings and usually run from 6.3V, but this issue could be resolved.

- Car radios could be made of high-quality cast aluminium with compartmentalised sections, a vibratory inverter for the high voltage section, radio and audio sections, and all had 0V bonding to the case by the shortest path at many points. The valve base connectors had clips. It would therefore be very expensive.

- The electrical system of modern cars has a high degree of interference screening and prevention, but at the sources of interference, such as the ignition, motors, and electronics. So that the electrical systems of the car do not interfere with the in-car entertainment systems.

- The voltage regulator regulates over a range of current loading and allows the battery to charge as fast as the dynamo can deliver current. But the battery is still used when the engine is idling. The current winding in the regulator applies compensations; A small increase in voltage when the charge current is higher, A further increase when a lot of electricity is being used, as a compromise to somewhat compensate for when the battery is being run down faster when the car is idling.

| |

| Two-pole two-brush dynamo, thank you for the picture https://www.dynamosdynamos.com/ Using just one field coil, as pictured, rather than two would limit the strength of the magnetism so limit the power generated. Later dynamos had two field coils, one on each side. Starter motors have four coils and four brushes. |

Dynamo pictured: -

Switch from a 6V to a 12V electrical system.

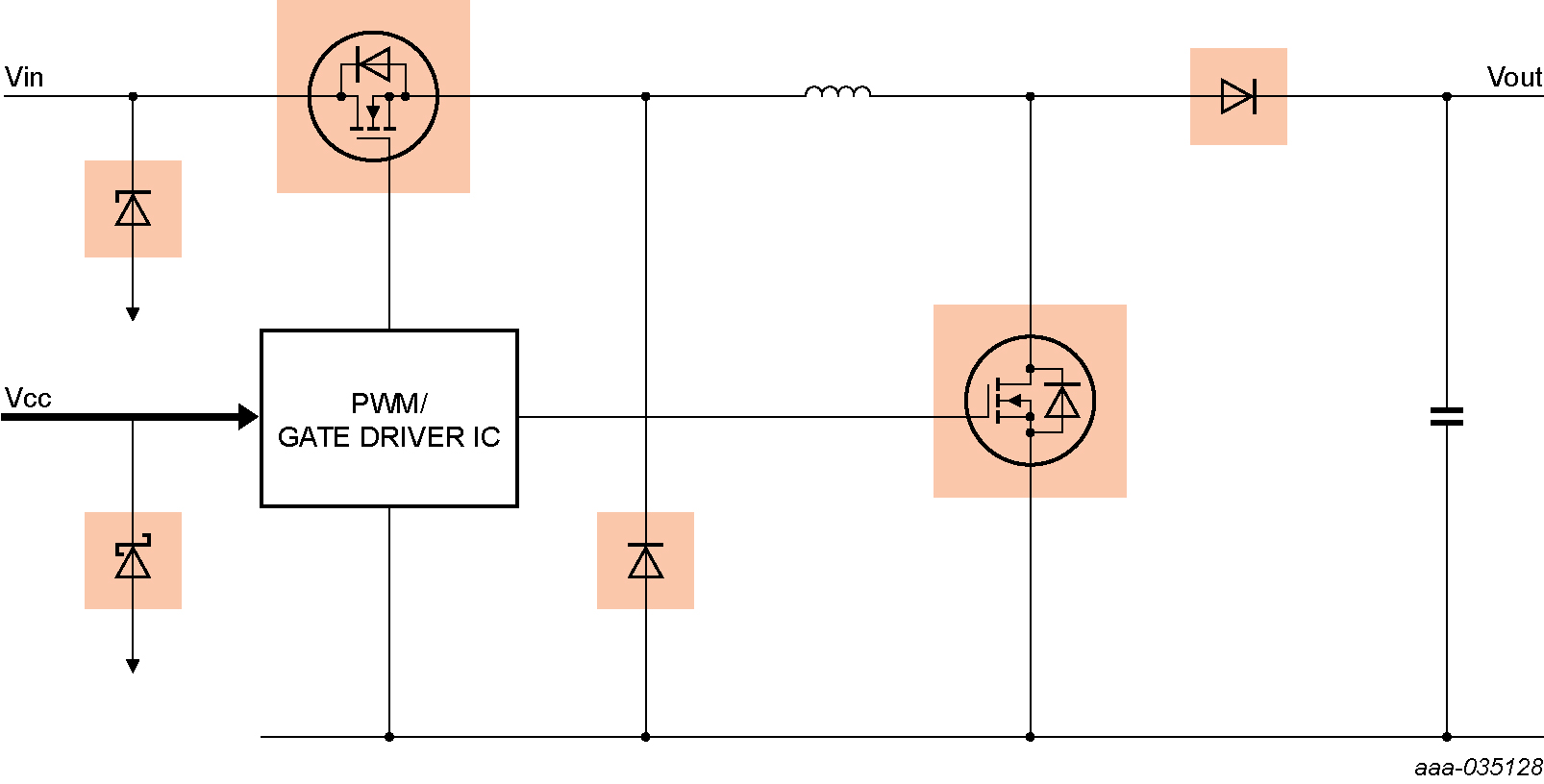

Electronics mostly start up above 3.5V, but the dynamo may produce less than 1 or 2V from the residual magnetism, so the field winding is connected by a relay to the dynamo initially. When the dynamo is generating more than about 3.5V, the Field winding current is controlled by a pulse width modulator (PWM) to regulate the dynamo output voltage.

Summary of this circuit version 01

Replacing filament bulb lighting with LEDs;

- You may be able to remove the dummy load, which is a bank of resistors. The electronics should still operate properly. That is, if one LED fails by breaking the open circuit, then all the LEDs of that circuit are turned off, which would, on a modern car, illuminate a dashboard warning light. But you may need extra electronics to pulse-width-modulation drive the red stop/tail light function. The PWM is either 100% for the stop light function or 5% for the taillight function running at 100 Hz.

- The tail light function can not be created using a series resistor; even if the LEDs were to illuminate, their colour may not be legally correct. On the other hand, all 12V car systems, including the lighting, should work down to 5V but not at their correct intensity.

- A 5W LED can be equivalent to a 50W filament bulb. An Austin 7 was fitted with 18W headlamp bulbs. Other bulbs are 3W but would be 5W or 20W for indicator lights now; these probably would not reduce as much as 90% using cheap LED units, and less wasteful units are probably not available.

- The LED drive may be by a linear current source, therefore the efficiency could be reduced to 25% or perhaps or by a switch mode power supply, in which case the efficiency may be 80%. Either way, LED lighting is beneficial for saving power.

- MP3433, 22V, 20A, no evaluation kit, will start up from 0.8V with an external 2.8V to 22V. It also includes a high-side low-loss diode function. The diagram on the website shows two audio inputs, CHL and CHR, that increase the output voltage when sound is detected. Monolithic Power Systems

- MP3435, 19A, 22V. There is an evaluation kit, 3V to 20V, which also includes a high-side low-drop diode function.

- Or MPT612, NXP includes MPPT software for this microcontroller.

- Most boost regulators or a microcontroller plus an SPV1040 to provide start-up power.

--------------------------------------------

Buck-Boost Switch-mode power supply to provide more of the available power: -

The Dynamo's power output can be at least tripled at high RPM and start producing power at a lower RPM without having to have been running at a higher RPM prior, unlike circuit 01. As in the previous circuit, the power available remains the same at the stated dynamo rating and RPM.- When an auxiliary electrical system is turned off, the dynamo will continue to generate a surplus of power for a few minutes. The dynamo voltage will rise the buck regulator will reduce the dynamo current. If this voltage becomes too high, an overvoltage clamp operates using 10mS pulses, shorting out the dynamo. This protects the buck-boost electronics and returns potential extra power back as motive force. That is the dynamo motors a little, and takes less force from the engine. Which is similar to what would have happened, except that the battery would have had to absorb some of that extra power.

- Whether a unit is home-made or manufactured, this would be an after-market product, so it does not need to comply with each of the different manufacturers' own standards that they impose on their suppliers. It needs to work with double battery voltage, 12V on a 6V or 24V, on a 12V car electrical system.

- The voltage control response time is slow because of the magnetism stored in the iron, made slower by the diode across the field winding, so the dynamo output crowbar will necessarily do more work, consequently. That is, the crowbar will operate normally when driving the car, and auxiliary circuits are turned off.

- But the average field voltage must be limited to the dynamo's original rating, 7V or 8V. The third brush adjustment is set to maximum, or reconnected to chassis 0V, to feed the field winding up to its maximum rating.

- Run a 6V dynamo and 6V car electrics.

- Convert a 12V Dynamo's output to 6V. And the extra power at low RPM is not available.

- Boost only regulator circuits -01 and -05; the output current would be half its expected value until the dynamo reached over 2,000 RPM.

- Increase the 6V dynamo to 12V electrics.

- Run a 12V dynamo and 12V car electrics.

- The Bipolar Junction Transistor (BJT) solutions have less protection, but it should be enough normally. A variant need not require a battery, but won't start up unless the remnant magnetism is enough for the dynamo to produce 1V.

- The electromechanical relay will blow fuses if badly wired, but it is a better solution, starting up from a fraction of a volt out of the dynamo.

- Two MOSFETs back-to-back resolve most protection issues. It may run from Dynamo power or battery power via the ignition circuit, but in any case, the field winding power comes from the dynamo's remnant magnetism in the field iron.

- Boost regulator is good because a few solutions will start up from about 1V and then power the main buck-boost boost regulator. But the best is SPV1040 solves most issues because it will operate from 300 mV to 5V, and will power the microcontroller and will start up from <400mV from dynamo remnant magnetism. That is, it should work reliably with a lower voltage 6V system.

- The cut-out function is more precise using a rectifier diode.

- It will start generating power at a lower RPM or start up more quickly.

- This circuit, by default, does not remagnetise the field negative chassis, unlike circuit 04.

- If it is necessary to reverse the car's electrics, including the field windings, the unit should be connected to the chassis and the field first, at least so that the snubber diode protects the field winding and the installer from a high voltage spark when the field is disconnected from the battery.

- A disadvantage is that more parts are required to provide functions that are integrated into Buck-Boost ICs or modules.

- Boost regulators that start up from a lower voltage but only work to the lower 5V. That may have other features, such as MPPT managers.

- SPV1040 0.34V to 5.5V may start at 300mV (voltage increasing 270 mV, voltage decrease to 140mV).

- SPV1050 0.58V to 5.5V <70mA or buck-boost from 2.8V to 18V <30mA has many other features. Boost works down to 150mV after starting.

- bq25570 0.6V to 5.1V works down to 100 mV 110mA includes a battery charger.

- bq25505 similarly 600mV start-up, 230mA.

- TPS61201, TPS61202, 0.8V enable threshold. 5.5V maximum, 1.3A inductor current.

- LTC3105 1.1V to 5.5V. but not start at 225 mV - 400mV due to #shutdown threshold of 1.1V.

- AP3015 or AP3015A 1V or 1.1V to 12V then shuts down <0.25V 70mA or 300mA 38V out.

Permanent magnets to replace the field windings.

The field could be continually magnetised using modern high-power permanent magnets. The over-voltage clamp function will then regulate the output voltage using PWM running at 100Hz. These circuits accommodate this option. You leave the field winding's output disconnected. The status LEDs will not indicate correctly, because there will appear to be a fault at times, causing a flashing green LED.Final circuit -

Selection of buck-boost converter IC or Module:

Unfortunately, supplying a 5V from the boost supply to ExtBias pin does not allow the IC to run at lower than the specified Vin 4.5V say 300mV. But the IC also operates in reverse direction and can use the battery or axillary small boost supply to start up and run from a very low voltage from the dynamo. This is described by application note on the IC using it as an uninterruptible power supply using super capacitors that discharge down to 0V.

This power supply therefore can not start up using dynamo remnant magnetism, unlike circuit -02 above. In this case it relies on the battery in order to start up. But a low power dynamo might be started up using the SPV1040 boost regulator to power the field so that second boost supply is included on the circuit, this would be beneficial on a car with magneto ignition and the battery was flat.

A link to my question, the , this answer given was no but I found the application note on the UPS which suggests the other way; https://community.renesas.com/power-products/f/power-management/57305/isl81401-evaluation-board/201072 Consequently the ISL81401A is unidirectional version or diode mode are not beneficial because the IC must be operated in reverse consequently diode mode is not possible, so another method is required to prevent battery current powering the dynamo side.

DE means Discharge Emulation. This mode is not used therefore FB_IN must be above 300mV and below VCC5V.

I read in Renesas support community that the IC must run in forward direction remain enabled before it will run in the reverse direction required. There are two application notes on the IC used for UPS one with supercapacitors operating in reverse down to nearly 0V.

- Therefore, I have changed the circuit FB_IN which is now battery output is driven high and FB_OUT which is Dynamo in is low unless the dynamo voltage is ~30V so that the buck-boost starts up driving forward mode (Battery to Dynamo). The FB_IN and FB_OUT are then driven on and off respectively and the battery starts charging from the dynamo.

- But it won't start unless the battery is at least 4.5V so if the battery is flat an axillary boost regulator from the dynamo powers VIN which forces Boost regulator. The Buck-boost wont be able to run in buck mode until the battery voltage has charged to >4.5V. Then it can run as intended generating extra power.

- IMON_OUT is set by resistor to a low current limit but just enough to just cause initial forward current to flow. Assuming that is necessary?

- IMON_IN is set to protect the MOSFETs, the maximum power transfer, and the current is limited by pulling COMP pin down by a microcontroller DAC port with a diode clamp.

- The Enable pin is driven low when the ignition is switched off, and the dynamo is not producing power to minimise battery drain.

- That is the plan, but I have not demonstrated it by modelling.

This group of ICs may or may not be able to operated in parallel with another of the same ICs, interleaved clock, and in reverse?

- Connecting most of the analogue pins in parallel is not the method recommended with this IC. Therefore, this is not possible; consequently, using one FB_IN pin for voltage feedback and the other FB_IN pin is connected to 0V, to enable a 180' clock output.

- ISL81601 IC looks like it may be a better option for synchronised and coupled status signalling between two or more phase interleaved mode operation.

- The balancing of the current between the different phases is more complicated than other ICs and requires op-amp circuits to share the power by driving the Feedback pins.

- Therefore, the dither function is available to improve the EMC profile instead.

- The SiMetrix simulation is for ISL81601 only. But there are differences between the ISL81401 and the ISL81601, with tolerances considered. Such as;

- ISL81401 IMON_IN and OUT maximum current set resistor is 41K (offset 1.2V / 29.0uA).

- ISL81601 IMON_IN maximum current set resistor is 53K (offset 1.2V / 22.5uA).

- ISL81601 IMON_OUT maximum current set resistor is 54K (offset 1.2V / 22.0uA).

Use the EVB test these options. The EVB can output up to 8A.

I have drafted a circuit that uses the axillary 5V boost regulator to trick the ISL81401 to start up even if the battery voltage is below 4.5V. Consequently, the regulator will run in boost mode even when the dynamo voltages is really higher than the battery and buck mode should be used but, in any case, the battery will be charged slowly until it reaches the right conditions and VIN becomes the battery voltage rather than the boost 5V.

There are some useful features.

- VIN is linked to the under-voltage sense and supplies the internal LDOs. Although I have added diodes so that VIN is powered from 5V boosted from the dynamo, just to get the IC running and the battery charged enough for the IC to work normally in reverse mode subsequently.

- EXTBIAS can be used to provide the switching transistors with a higher 8V gate drive. Or the pin can be connected to 0V.

- VDD of 5.3V is used for gate driving.

- VCC5V is probably cleaner, better for the analogue electronics.

- FB_IN is coupled to the battery output, but in case the battery is flat, the processor DAC pin VFB_DAC must be driven high enough to ensure FB_IN > 300mV so that reverse operation is enabled.

- IMON_OUT and IMON_IN measure the input and output currents, where 1.2V is the current limit. They must be buffered, then they can be connected to the microcontroller A/D inputs.

- Their outputs are offset, so a little negative current still appears as a reduced output source current.

- The current limits can not be set from the microcontroller ports easily because variable resistors are required. Control is by the comp pin to manage power output.

- The input is offset -80mV to 150mV at CS, for example.

- The two current sensors have a common mode range that includes 0V to +40V.

- 60' or 120' clock options are not available, and the 180' clock two-phase interleaved clock is also not available.

- PGOOD is not used.

- EN/UVLO This pin can be left floating, but it should be used to turn the buck-boost off and put it into the lowest shutdown mode when the dynamo is not producing power, and the ignition is off.

MOSFET power switching optimisation - The gates of the power MOSFETs must not include series resistors so that the switching optimisation circuit can operate.

There are simulation models available, but they are difficult to find, and you need to register using a company like a domain email address, rather than a general email like Gmail. address. https://www.renesas.com/us/en/products/isim.html

- The battery voltage must be greater than 4.5V and be connected to VIN for the buck-boost to work; it then works in reverse. FB_IN monitors the battery, which must be greater than 300mV and less than VCC5V, which, in any case, it must be. Therefore, diode emulation mode is not available.

- Constant current limit mode rather than hiccup mode, this is done by placing a resistor from LG2 to 0V of about 20K.

MAX20048 2V (4.5V) to 36V EVB £230, up to 16A input, 5A output. £8.40

Blue Vi - Dynamo voltage. The rectified voltage rises above the dynamo voltage to 21V during start up period, 10mS for ~1.7mS, using power drawn from the battery.

Red Vout - Battery voltage.

Pink - compensation pin, I have not optimised the compensation, so the waveforms look thick due to instability. It turns out that when the input voltage and power drop to zero, this pin's voltage is raised a little by a small current from the battery until the EN enable pin is held low, to stop it taking battery power when the dynamo is not running.

Grey Ven - enable pin. This pin needs to be pulsed or pulled low to stop the IC from taking power from the battery.

Green I(Vi) - input current after the rectifier. An additional circuit simulating the microcontroller reduces the power drawn from the dynamo when the input voltage is 2-3V to prevent the controller from shutting down.

Emerald Green I battery - output current. Is briefly reversed after ~6mS. If the battery voltage is higher than the set point, the current does not reverse in this controller, in comparison with other controller ICs. There is a small current drawn from the battery when there is no power input until the controller ICs' enable pin is pulled low.

To repeat the point - The controller needs to be disabled when the dynamo is not producing power otherwise once running it will continue to draw current from the battery.

It seemed that the IC cannot be tricked into starting up using a boost regulator from 400mV Vin but it turns out that it takes a long time for the model to simulate and it needs to run for 10mS which in real time is very much longer before it has completed its start-up period. That was putting 4.5V on pins IN and OUT and also ensuring CSP1 and CSN1 are less than 300mV above IN, the datasheet says VIN but there is no VIN pin.

I have a support question waiting for a reply:

CSN1 CSP1 what is their maximum voltage? - Q&A - Power Management - EngineerZone. these pins must be less than IN pin voltage although the datasheet does not say that clearly. Input current sense must be below VIN but there is no VIN pin.

Partly developed circuit and PCB: AL-0060-04B buck-boost MAX20048

MAX20048 using an auxiliary boost regulator instead of a relay. Not recommended.

A variation of the circuit could use an auxiliary boost regulator rather than a relay to start up. But the dynamo's output voltage must exceed ~3V with the field powered by the axillary boost power. The MAX20048 can start up from >4.5V easily enough. I therefore do not recomend this varation of the partly developed circuit: AL-0060-04B buck-boost MAX20048 Boost

MAX25431 6V 36V, EVB is £120 initially start 7V, 3-25Vout so is not suitable £1.80

MOSFET switching optimisation

- It is most likely that the IC would not run its normal initialisation to optimise the switching of the power MOSFETs, if tricked into starting from a lower voltage?

- Alternatively, the IC may adjust whilst running anyway, and nothing further needs to be done.

- Putting auxiliary 5V into VIN works in the simulations. No doubt because vinsns and voutsns are connected correctly, buck and boost modes are determined correctly. It may therefore be wrong to consider these alternative connections a trick. In other words, without a positive support reply, testing the running in an EVB might work out okay, but a different part should be evaluated.

This IC should work well in a 12V system, but would not offer much extra power at low RPM in a 6V system.

Works with low voltage input, provided that an auxiliary 5V power supply to EXTVcc and rectified dynamo input to VIN. Unlike LTC3789 there is no need to work around anything to get the IC to operate with a very low input voltage in the LTspice. But doing so is not covered by the datasheet. That is the axillary supply needs to be greater than 4.6V and below 14V then the module functions.

This module, therefore, is only fully useful in a 12V electrical system, though it will work, but without producing any extra power at low RPM in a 6V system.

LTspice model consume a lot of current (20-28A) as it starts up, briefly probably so that the power transistors drive is optimised. When adapted to current limited and rectified input voltage the simulation works up to a point where the simulation runs so slowly that it does not complete. There is always a smaller current pulse taken for a millisecond from the battery then subsequently the cut-out function prevents that occurring.

These simulations did start to run from very low input voltage but not properly.

EVAL-LTM4712-A2Z four modules 48A for £160,

EVAL-LTM4712-A1Z two modules 24A out. £142 + VAT.

These EVBs - may not be possible to wire them so that one current monitor is connected to the input and the other connected to the output. I don't know if it would be possible to power VIN from auxiliary 5V and power EXTVcc from the input supply? My support question did not get answered.

The field winding cannot be taken from SW2 pins and rectified, but the pins are output so that an snubber R+C can be fitted. (TP15, 28, 36, 44).

These models attempt to start up with an out of spec low voltage but don't run;

AL-0061-03A ltm4712 buck-boost - op current Battery mppt.asc

These models run okay then run so slowly that they virtually stop after 2 or 3mS. RUN and EXTVcc are enabled and powered with VIN at a fraction of a volt.

These models are operated within datasheet or slightly wider spec. based on ADI models;These models (-1) do not support very low voltage start-up, but shows the current limiting Maximum Power Point Tracking working after the simulation has run for a longer time. The reverse current flow battery to the input occurs until the RUN is driven false.

Starting the IC from low voltage and current question to the support forum did get answered, so using an EVB is a good strategy to test start-up operation. It probably should not be done in anycase.

- MOSFET switching optimisation

- It is most likely that the modules do not run their normal initialisation to optimise the switching of the power MOSFETs, so after the dynamo is running, disable and re-enable the IC to get it to initialise properly within the specified voltage range. Possibly sequentially?

- Alternatively, the modules may adjust whilst running anyway, and nothing further needs to be done. In any case, the module is not being tricked into working, although this very low voltage start-up using the EXTVcc is not illustrated in the datasheet.

- These buck-boost modules run bidirectionally. If reverse current flows from the battery, the rectified input voltage rises, and the modules' RUN input must be set to False. This occurs if the battery voltage is higher than the set voltage. The condition is detected by the rectified input voltage rising above the dynamo output voltage or the current direction being reversed. The output current direction can also reverse briefly if the battery is supplying the field current, but this should not be allowed to continue either.

LM51772 is suitably wide -40 to 125 °C. 0V to 55V with 3.5V bias I2C interface £7.30, EVB available for £212.

or LM51772-q1, which is automotive grade.

- Current limit is settable between 5mV and 70mV with 1% accuracy and 2.5uV offset, 2.8V to Vin. Consequently, it can not be used to limit start-up current, but it can be used to manage cut-out function and to limit the output current to 2.5A to 35A, say. For starting up at a low but maximum power, the COMP pin should be driven by an open-drain variable voltage clamp.

- Cable compensation may be useful from the optional current sense input if it is placed on the output, which I guess might be the only place where current sensing will be useful. But I don't think it can be set by programming through the I2C bus, but a resistor has to be used; therefore, the function is probably best not used.

- BIAS alternative power for internal circuits and Gate Drive, said to be from 3.5V, but power MOSFETs need ~5V drive.

- Vin sense 0 to 55V, Vout sense 1V to 55V.

- Under voltage range falling from 2.8V to rising 3.5V

- Output discharge - may not be possible to turn off? but can be set to 25mA, the lowest setting *** this needs to be resolved? ***

- This controller is bidirectional - I do not know the best way of inhibiting this function, but disabling it should work because it should also start up on low input voltage easily enough.

- This IC does not tune the gate switch dead time, but it is set depending on the clock frequency setting. Therefore, there probably is no high current or voltage generation for 1mS, unlike the ADI parts.

Other ti.com ICs and modules - datasheet do not state they work from 0 Vin;

LM5177, LM51770, LM517701 minimum 2.8V if Vias is >3.5V.

LM251772 Bias or Input start up 3.5V to Vmax. 0-70'C so it is not suitable.

LM5118 does not work below 3V and requires two rectifier circuits.

TPS55288-Q1 or TPS552882 includes two 16A output transistors, but is limited to 6A. I2C bus. About £5. pspice model available.

- Input crowbar dynamo over-voltage protection - optionally, there is hardware doing this function. But the power generation needs to be managed so that the OV mostly does not need to operate, also by managing the field PWM.

- Power the field winding and the power supply from the battery, but ensure that the dynamo is generating enough power to power the field winding. That is the circuit that doesn't include a diode to the battery, which must use Field and Output current monitoring to provide the cut-out function and also control power saving modes.

- Field PWM and output power must be managed to use the optimum power transfer.

Circuit with options:

- The switches set -

- 6V Dynamo, 6V Battery

- 12V Dynamo, 6V Battery. The power output would be half expected until the dynamo reaches twice its rated speed, ~2,000 RPM. This option is therefore not highlighted.

- 6V Dynamo, 12V Battery

- 12V Dynamo, 12V Battery.

- The up and down buttons set the battery terminal voltage to compensate for the cable resistance. So that the battery terminals' voltage is 7V when the dynamo meets the battery's need, when the generator light is green.

- The last switch could be used to offer a simple RED generator light. Except under a fault condition.

- Output current limit.

- 100%

- 120%

- 150%

- Maximum

- The High charge (F2) or Medium charge (F1) Contact and pulled up to B+, then the low charge is not selected. Low charge could be used to turn on flat battery recovery mode for a low or high impedance battery fault. Otherwise, wire one of the unit's connector terminals to the ignition, and the feature will be turned on. That is to bypass the warning and force battery recovery mode.

- The dashboard generator LED. Flashing slowly indicates set to flat battery recovery mode is running.

- RED - Not charging,

- AMBER (GREEN and RED) - charging but not meeting the need.

- GREEN - Meeting the needed, and the battery voltage is correct.

- White or Blue LED - Extra power, buck mode, or extra power at low RPM, boost mode, is being generated. If an LED is fitted.

Error conditions displayed by fast flashing LED colours;

- Dynamo has not started up, so maybe the Field needs to be flashed to reverse or magnetise it. - Fast red LED flashing.

- No battery detected, fuse or wiring fault. - Fast Green LED flashing.

- Open or shorted field winding, fuse or wiring fault. - Fast amber LED flashing.

- GREEN and RED - Flashing alternately and slowly, Fault, wrong or low battery voltage setting. Set to 6V, but a 12V battery was found. But the cause may be that the battery voltage is very low; in that case, you can use the Low Charge setting to recover the battery by setting the battery voltage and continuing to run.

- A variation of this circuit uses an auxiliary boost regulator to start up the microcontroller and the buck-boost regulator. The maximum power must be limited until there is enough voltage ~4V, to keep the microcontroller and the Field driver running and when the battery voltage has recovered at least 3V. In this case, the relay is not fitted.

- The microprocessor placed is not the optimal choice, but it shows that a 48-pin microcontroller should just about fit.

- The unit should withstand starting with jump leads to another battery, but not necessarily to a high-power fast-charging unit. An inappropriate connection to the field or the dynamo without blowing the fuses.

- The unit starts up with a fraction of a volt generated from remnant magnetism in the dynamo. If the battery is flat, it should start on the crank in a car with a magneto.

- Provided that the engine continues to run, the buck-boost will continue to run and can provide a small but extra power that the dynamo would not have produced originally.

- The extra transistors and circuitry for overvoltage are an improvement in circuit 02 and are similar to AL-0060-05A

- MAX20048 draws current from the battery at start-up, which causes the rectified input voltage to rise to ~24V, but I do not know if the voltage could rise enough to damage itself and other parts.

Conclusion - supplying more of the power generated by a dynamo.

|

| AL-0060-04B MAX20048 draft PCB Start by putting down and grouping the footprints by function. There are many errors to correct. |

- 15 to 60V needs to be adapted to optimise over; 2V to 8V or 4V to 16V

- An internal power supply of 12V needs to be generated by a small buck boost regulator to 12V

- Infineon advise that the wound components also need to be revised. Though I think you can get by with what is fitted.

- Other evaluation boards for SPV1040 or SPV1050 in boost mode need to be used.

Magneto for ignition, plus lights, plus battery charging;

Villiers motorbike engines, magneto's - publications ~1950;

- Magneto with two lighting winding types and the ignition pair of windings at the top of the picture. Pictured is the four-pole type, but a 6-pole with 6 lighting windings was also made.

- Diagram the ignition coil with low voltage and high voltage windings, contact breaker points, and the capacitor. Plus two coils for lighting, see top and bottom,

- Diagram showing the working of the ignition magnetism, but the HT winding and the capacitor are not shown; My text, a b c, explains different aspects of the spark generation cycle.

The simplest spark ignition uses a moving fixed magnet and a stationary high voltage coil wound on soft iron. A blunt wedge edge rotating magnet, and a stationary blunt wedge edge iron with the high voltage coil. Parts pass each other closely, generating a high voltage spark. The engine, such as a lawnmower, has to be cranked quickly past compression to start.

- This large, low-revving veteran engine has a spring-loaded magnet which was released on a trigger, which moved the magnet rapidly past the coil at the correct angle. Ignition is required. You can see that happening in this video at 6.50 minutes.

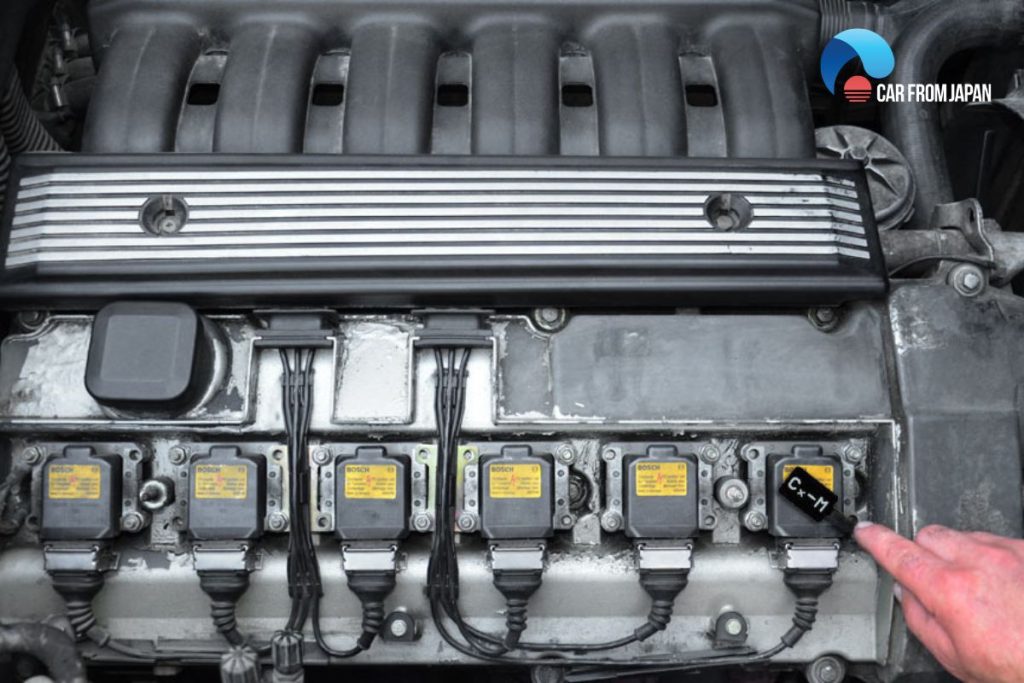

- Picture, from; The 4 Types Of Ignition System And How They Work, shows transformer modules on top of the spark plugs. The ignition system is probably powered by capacitors discharged into the transformers. These ignition coils are smaller than the traditional coil, no doubt because they don't store energy in the coil. That is, it is not the Kettering ignition system. But a short burst of high-frequency oscillation would also work.

The Ford Model T's ignition has a low-voltage distributor at the end of the camshaft with approximately equal sections of insulator, metal contact and a rotating roller contact connected to 0V chassis. Its body is rotated by a lever on the steering wheel column to retard or advance the ignition, and the spark is generated continually for about half a piston stroke. The later trembler boxes' contacts have a slight wiping action similar to very long-lasting post-office equipment relays and switches.

- A magnetic sensor instead of the contact breaker points,

- A two-transistor saturated core high-frequency oscillator and transformer to step the voltage up to about 300V. This inverter's power is briefly reduced during the capacitor discharge period, and the SCR needs to turn off.

- A capacitor was charged and then discharged into the coil, which was now used as a step-up transformer - the discharge was by an SCR, which was reliable. The current is higher but limited by the leakage inductance of the coil, but could cause a more severe RF emissions issue with a car radio?

- The first circuit is similar to an alternator regulator. Although it has a slow response, it is robust.

- The second circuit requires a connection to both ends of the field winding and has a faster response time, similar but not the same as that of the electromagnetic regulator and snubber resistor.

The Mini Metro was launched in 1980. Cars had now become what the Lenton sport bicycle already was in 1946, a vehicle you could use with just some minor servicing points to observe and deliver when new without faults.

Earlier steps towards easier travel

After Richard Trevithick's high-pressure steam coach of 1801 and his steam train, came the velocipede, an early type of bicycle.i

Other developments

|

| An owner's manual shows you how to service nearly every- thing on the car. Car makers stopped publishing these, but The Haynes Manual replaced them also show you how to fix everything on the car. |

Living within our means;

Doomsday clock and this year's statement; https://thebulletin.org/doomsday-clock/

I've suffered with illness due to air quality all my life, or at least since I was six, after we moved from a village to a London borough town. I am retired now. In conclusion, we've suffered from what we burn and breathing fumes for thousands of years. Blamed pollen and hay, for example, but those seem to be allergies that turn out to have zero issue when I get away from vehicle fumes and dairy products.

Biofuels Are A Climate Policy Disaster, New Data Reveal - Sabine Hossenfelder reports; https://www.youtube.com/watch?v=6Nu-o3QjCKM

This video covers some of the same as this blog https://www.youtube.com/watch?v=LYGD07yEO14

Harry Westlake, cylinder head designer, https://www.youtube.com/watch?v=-qe1iWZf7v4

The Victorians promoted sport to improve public health so they would not be infected by disease spread by common people. Now the Olympics are paid for indirectly by governments to promote arms sales. When they are built, they take away homes and leave damage and debt. https://davidswanson.org/talk-world-radio-how-the-winter-olympics-is-melting-away-the-worlds-snow/