Changed; 26/07/2024 - 25/07/2024

Sturmey-Archer generator hubs (GH6, GH8, GH12, AG, FG), variable gear hubs (AW, FW) and bicycle lighting.

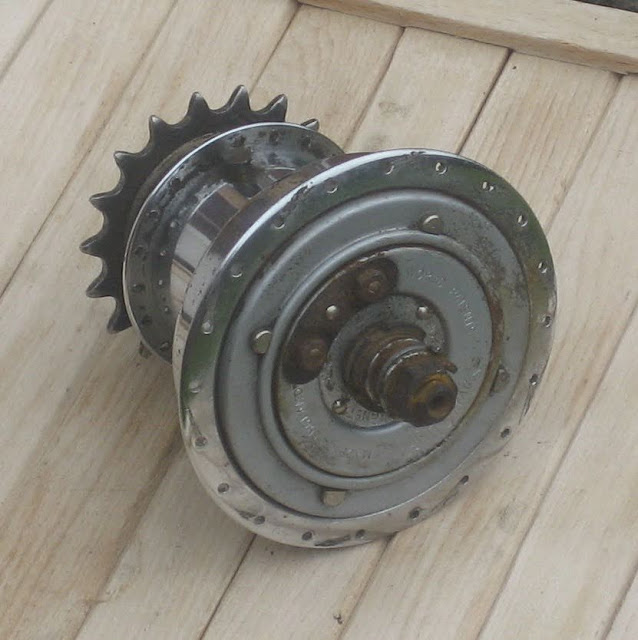

Pictured; Sturmey-Archer, AG - 3-speed Dynohub, dated July 1953;

3-speed wide variable gear hub and 6Vac, 2W generator, 40 spoke.

Summary - Mechanically the Dynohub was made like all Sturmey-Archer / Raleigh products of good quality materials, to be maintained and serviced in a straightforward way over their very long life span. I have read that Sturmey-Archer Dynohubs were sold with a 50-year guarantee in 1950 or forever if was on a Raleigh bicycle. But they were not redesigned to use more powerful magnets, therefore be more efficient, have more power output and lower material costs until the 1982 when such a Dynohub and lighting was developed, prototypes sampled, but never sold. Manufacture of Dynohubs by Sturmey-Archer ceased in 1984 (See Sturmey-Archer Story by Tony Hadland).

Content;

- Dynohub repair, making a magnet keeper, re-magnetising theory and practical suggestions,

- Newer and older 3 and 4-speed AW and FW variable gear hub lubrication and maintenance,

- Lighting circuits and regulator circuits,

- Motors that can be used as generators.

- Addendum; Alternative LED lighting circuits that can be made from salvaged parts,

- Addendum; Bicycle bottle generator experiments using a stepper motor salvaged from a printer,

- Blog; Electronics project that can take and provide more power at higher bike speed with good efficiency when required for battery charging and powering other devices.

The Dynohub pictured above;

The first impression - the sprocket turns both directions without engaging and was floppy but after dismantling, reassembling, and lubricating the gear hub is free running, it should feel loose which it does. The case is bright chrome with some rust and the internals seen from the outside are a dirty black dry oil and dry inside. It has not been oiled adequately probably not assembled correctly and the toggle chain is missing - this Dynohub's condition is unknown.

The dynamo - feels dirty but does not feel like there is any internal rubbing. Turning the dynamo is definitely lumpy as would be expected as the poles line up but the magnetic force is quite high - which could mean the winding is shorted and/or the magnet is in a very good state of magnetism.

Once the terminals were tightened there was good continuity. Shorting the contacts will make the magnet detent force stronger (harder to overcome) as should happen and indicates that the winding is not shorted. That is as far as I can tell over the friction from internal dirt at first but now that everything is put back together properly, lubricated the hub runs fine and appears to be in good order.

On opening the Dynohub it becomes apparent that the magnetism is not particularly strong and it is quite easy to slide the winding assembly against the magnet. The magnet is old for the time, probably AlNiCo type that would never have been particularly strong. The air gap, as expected, is large by modern standards of motors and generators but that is because it uses the same weight carrying bearings as the wheel this lowers the Dynohub's power a lot. It is likely that the magnet was not fully magnetised but probably magnetised using a calibration procedure to set the required output current. AlNiCo has better resistance to corrosion than newer material types of the time.

Pictured above right; Stronger ceramic/ferrite type magnet from a 1950s or early 60s TV.

Objective;

To discuss the electrical issue with some textbook motor and generator theory. This type of generator is the same as a single-phase permanent magnet synchronous motor. These motors used to be used in electromechanical central heating timers. They are also similar to a hybrid stepper motor that has; two, three, four or five phases, usually operate at low speed and are found in printers to wind turbines. All so-called bicycle dynamos but have no brushes and the term is incorrect. "Dynohub" does not appear to be a trademark but the logo would be copyright. If the magnet is re-magnetised successfully then the Dynohub should produce a higher current at 6Vac than the rated 300mA at a lower speed.

Graph - current can be drawn up to the same limit irrespectively of the generator speed and then the voltage will drop sharply. The winding's series resistance has not been included it causes the voltage to drop as the current increases.

Small graph - With no load, the output voltage increases linearly proportionally to the speed of rotation. A lightly loaded dynamo is the same as a tachometer and would make a good speedometer.

In a discussion on Facebook, I have been shown the patent below which claims a method of providing some voltage regulation rather than current regulation that I suggest above - load voltage regulation is claimed. The magnet is machined in a way to form discrete poles so that the magnetism does not slip around and presumably be weakened more quickly. The claim is also that the current reaches the desired level quickly - That would occur in any case by having a lot of poles and a high number of turns/volts coil. The graphs with the patent do show some voltage regulation when loaded. The description also mentions reactance of the winding being a limiting/regulating factor but I am not sure how this helps to model a generator?

The patent is dated 1936 - I found it difficult to understand and I do not think the patent contributes to the dynohub design.

Tests below show that the dynamo does not behave as an entirely constant current source and the voltage and current varies with with speed. Therefore this diagram is more like the what happens.

Efficiency;

The losses in the Dynohub are due to;

- Bearing friction which is very small in this case of a thin oiled bearing.

- Magnetising force - the power needed to change the magnetism polarity (north to south, south to north) in the iron conducting the magnetism to the winding this is very small and might be 1% of the power available. That is the available power generated and the magnetising power used increases with frequency. This can be determined by looking at the B-H curve for the mu-metal.

- Eddy currents in the iron conduct the changing magnetism this depends on how thinly it is laminate. GH6 bike Dynohubs are probably a little lossier because the metal is not thinly laminated but is just three laminations compared to a transformer, or a motor which has many laminations. I have read an anecdote of someone getting one or two hundred volts from a Dynohub by taking it off a bike and spinning it fast, which suggests that eddy current losses did not limit the output voltage at high frequencies and probably are not a significant issue.

- Copper losses are the losses due to the resistance of the winding (which is 5 ohms) when current is drawn is a significant factor, though not discernible by the cyclist; I2R which is; 0.45W = 0.32 x 5 in this case.

- This power loss is significant 25% at rated power 1.8W.

- A different effect is observed and said on social media: a Dynohub which on small wheel bicycle's turns faster than cycling a full-size bike, and tends to burn out filament lamps, that is the output current increases with speed.

- A filament lamp's current self regulates a little when supplied from a voltage source such as a battery by comparison. But the power tends to run away when supplied by a variable current source. For example a quartz halogen filament lamp's cold resistance is about 1/20th of its hot resistance.

- A vintage GH6, 8 or 12 Dynohub are less efficient because the magnet is lower-powered but a Dynohub uses more copper and iron in compensation but losses are still be higher.

- A modern hub generators losses are more than 10% of the available power when not connected but varies between makers of modern generators. These are magnetising and eddy current losses. The path of the alternating magnetism seems unnecessarily long. See Skjegg blog link below for measurements carried out on some modern hub generators.

- See the addendum with pictures of motors at the bottom of this page for more efficient designs.

- But the losses are a lot higher in a modern hub generator system (up to 45%). See Skjegg blog link below for measurements carried out on some modern hub generators. The electronics waste power instead of using more sophistication to just take the power required.

- The amount of power wasted in a modern hub generator additional system may be 7W compared to 2-3W below or 1W. That is if I have understood the two blogs correctly.

Voltage regulator;

AL-0035-04B Shunt regulator used with vintage filament lamp lighting to improve voltage regulation. If one lamp fails then the other lamp will not become over-voltage and also fail. Prevent over-voltage and filament lamp failure at higher bicycle speeds or faster spinning small wheel bicycles.

The power wasted is up to 2W (2.5W including the dynohub) and any surplus power is returned to the Dynohub as forward movement of the bicycle so that the extra effort that the cyclist puts in does not increase at high speed. A Zener shunt regulator like this is not fitted as a standard and was not made by Sturmey-Archer but they can be made or purchased and added. The switch shown is usually not fitted but another switch is fitted where it is not beneficial.

The shut regulator only takes what is required or a little surplus not used by the lighting. This lighting system probably takes less power from the movement of the bike than modern bike dynamo systems take. Consequently, there is no surplus for battery charging or anything else. The design project https://blog.andrew-lohmann.me.uk/2020/09/electronics-design-project-bicycle.html offers the best of both strategies and runs LEDs.

1. Simple but will flicker annoyingly, I expect and will run from 4V.

2. This will flicker much less will run from 5V. 2W Zener diode, >200mA Shotley diodes.

AL-0035-01E

Where modern LED lighting may use less current than a modern hub generator produces the circuit below takes less power from the bicycle movement and could be home constructed. The voltage regulation is better than the shunt regulator above.

AL-0035-04C phase control voltage limited power regulator. This is slightly more efficient than the Zener clamp. But adding a 5V6 Zener at the output and removing the triac and surrounding circuity could be done instead. It is likely that one USB light will take more power than the other. It is important to set the LED light levels low so that both lights get enough power most of the time.

Input; 5.8V = 3.9V + 1.1V + 0.6V.

Output; 5.0V = 3.9V + 1.1V + 0.6V - (2 x 0.3V).

Therefore the output voltage full load; 4.8V = 3.9V + 1.1V + 0.6V - (2 x 0.4V)

No allowance for temperature has been calculated but the voltage is likely to be 4.5V to 5.5V.

The extra power that was wasted by the triac (z01 ST) <300mW from a graph in the data sheet. Compared to <1.5W for a Zener diode shunt regulator solution. Or zero power wasted if it is all used.

Provides enough voltage to run a USB device but the voltage being nearer the minimum be too low for that the device to charge at a good rate at the same time not so high to exceed 5.5V maximum.

These are untested designs.

-------------------------------------------------------------------

Dynohub maintenance;

Magnet keeper to prevent demagnetising - in case it is required;

The magnet will demagnetise if separated from the armature so if you remove the armature you need to replace it with a keeper such as another armature. A magnet keeper is a piece of soft iron that conducts magnetism very efficiently. Mu-metal that transformers, motors, generators, and the screen on an old colour TV Cathode Ray Tube use are ideal. The metal should not be bent or hammered because this hardens the metal and reduces the metal's desired qualities so you should minimise the amount of work you do on the metal.

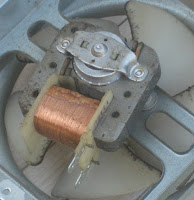

Colour TV, Cathode Ray Tube magnetic screening is made of mu-metal. Microwave oven transformer with high leakage inductance - pictured left. Single-phase shaded pole induction motor - pictured right.

Mains frequency transformers come apart into a bobbin with copper wire, and "E" and "I" section mu-metal. The microwave oven transformer with a high leakage inductance pictured is welded and will probably be difficult to take apart, therefore look for another transformer. The motor's mu-metal will need some more cutting to make it useful. Very old mains and loudspeaker transformers are not varnished so come apart easily for example. The colour TV cathode-ray-tube screen is the best source of mu-metal as can be seen in the picture.

The Plan to make a keeper;

To cut a piece of mu-metal and carefully bend it into a radius. In more detail like a C shape but with the ends overlapping. I had planned to make the metal strip with one end folded up so it could be pulled out but the magnet turns out not to be as strong as I was expecting.

The estimate of the dimensions from outside dimensions;

- BSA and others - many sizes not known.

- Sturmey-Archer;

- GH12 (1937-44), 111mm outside diameter (from pictures). 12V, 2.7W, and 3W,

- GH8 (1939-44), 90mm OD (from pictures), 8V, 1.2W,

- GH6 (1944 - 83) dynohub, AG and FG variable gear dynohub. 6V, 2W (reduced to 1.8W subsequently).

- The estimated magnet internal diameter measuring inside the bolts is; 70mm. and width 24mm,

- The length required of mu-metal required is the circumference; 210mm = pi.D.

- Therefore ensure there is at least 230 x 30mm mu-metal.

I understand that all post-world war two Sturmey-Archer dyno-hubs and gear Dynohubs are the same and parts are interchangeable. The external appearance changed from time to time though. Earlier hubs have 32 holes front and 40 holes rear but later hubs all have 36 spoke holes.

Picture - Making the keeper; Find a glass jar of about the right diameter, wrap it in a rage, and then bend the mu-metal around the protected jar. The kitchen scissors are described as cut anything up to tin plate steel and are more suitable than the tin snips on the right. A hammer, anvil (use a vice with care), and a file to clean up the cut edges.

I have some mu-metal and have cut a piece 30mm x 260mm x 0.5mm - it looks messy because I used kitchen scissors and it would be better cut with a guillotine to make a magnet keeper for a GH12 hub-dynamo. I bent the strip of mu-metal around the glass jar wrapped in a rag to form into a C shape radius.

-----------------------------------------------------

The variable hub gear and other bicycle parts are made to loose-tolerances So that no moving parts should feel stiff or tight. That is they tolerate grit and dirt with the minimum of harmful wear. Frequent oiling is necessary to lubricate, flush out dirt and moisture.

By comparison, the synchro and servo, gear-heads and tacho or Synchro resolver pictured right are expensive precision components used in precision instruments. There is virtually no slack or stiffness in them. They were supplied in the tightly fitting plastic pack shown and were made in the 1960s by Vartec. These components can be stacked end to end and they fit firmly. Synchros and servos are used in a clean dry environment but will continue to work in a dirty environment with some moisture. The military uses them but they are rarely used in industry now.

Synchros and servos were developed for use to compute gun rang during World War 2 one of the lectures at college I attended was one of those wartime boffins who worked on gun ranging. They do a very quick addition sum of angle inputs approximation to compute the range.

Disassembly of the dynamo section;

The magnet is brittle and is pressed into a soft metal enclosure that has water excluding greased lip. There is also a waxed cardboard washer protector shown with intellectual property details printed on it. It is not necessary to move the wiring and it is best avoided doing that unless there is an issue with continuity or insulation.

A dynamo hub bearings and the variable gears can be serviced without separating the magnetic parts. In this case, the magnet moves around the winding freely and the inside looks clean enough not to require removing the armature and inserting the keeper. Although the amount of cleaning will be limited anyway.

I have used a mole wrench to hold the shaft by the not threaded flat sides, a 15mm ring spanner for the nuts on the shaft, and a 5mm nut-spinner for the 8BA nuts that hold the dynamo section together (the 5mm sockets I have are too fat). The magnet has 20 poles in this picture.

I have wiped to clean the surfaces then rubbed the surfaces with grease. I have also pushed the coil a little way out of the magnet it moves too easily it should be difficult to move, indicating that the magnet has weakened over time. But turns out that the output current is correct so the magnet is okay.

The bearing can be seen the adjustment can be made from inside or also the adjustment can be made with the dynamo section assembled using the remote adjuster picture on the bottom left corner of the tray of parts. I recommend that the variable gear section be opened and checked, but if you are not going to touch the variable gear section, ensure that this bearing is adjusted correctly.

If the hub does not have an oil port then the bearings do need to be greased. This Dynohub does not require greasing and this internal bearing does not have a water-repelling seal. In this case, oil gets to all bearings and other parts.

------------------------------------------------------

Inspecting the variable gear section bearings, greasing the water-repelling seals and adjusting;

Note that the GH6 front wheel fitted type hub dynamo bearing adjustment is carried out from the non-dynamo side. See; https://youtu.be/2SnEkpU0YeU

Video shows AW hub disassembly and that the drive side bearing is set to 1/4 to 1/2 turn slack and the non-drive side is set after the drive side bearing to 1/2 turn of slack. There are some differences and I have shown a tray of parts for the dyno-hub with the dynamo side bearing disassembled.

One difference with the variable gears only hub is that there is no press-fitting bearing oil trap so that a little lubrication from the variable gear will spread into the dynamo section. The rust seen in the picture is a little greasy. The hub should not be greased other than a little to hold the balls in place so that the bearing can be assembled. This is a little different to the advice given in many videos.

The outer bearings have a grease-filled grove to repel water that grove needs any hard old grease to be scraped out and new grease packed into it. These water barriers are the only parts that should be greased in a variable gear Dynohub. There is another water-repelling greased grove between the stationary connections plate and the rotating hub. The large bearing in the variable gear-hub has a little oil running out taking dirt and moisture with it.

Note; It turns out that variable gear is complete and disassembly and assembly is straightforward. Do use the video or other sources for maintenance information. You should not need to disassemble as far as the video shows you but also look at the planetary gears for timing marks an AG or AW does not have them but some variable gear hubs do and they must all be aligned when you re-assemble the hub.

-----------------------------------------------------------------------------------------

Hercules Balmoral 1975 AW variable gear hub, by comparison with a Dynohub;

- Put grease in the grove around the bearing to form a water seal, I have put the grease in the nut but not in the bearing side yet.

- Hold the shaft still in a vice lightly on the flat sides of the shaft, set the slack in the bearing by tightening the cone-nut then loosen 1/2 turn (with your fingers but ensuring that the nut goes up the bolt and there are no false tight points due to dirt in the thread). Then tighten the locknut whilst holding the cone-nut still with the thin spanner.

- Modern bikes with shorter stroke brake leavers and a magnetic sensor for a bike computer will need the bearing set with less slack say 1/8 turn and the spokes kept very well adjusted. But do not expect such a bike to last 100 years with the balls in the bearings changed every 100,000 miles.

This 1975 AW was in sound order internally but leaked rusty oil after oiling and riding.

Another AW dated 1985 did not run or change speed smoothly until it had been oiled regularly for a year or so. During that time black muck came out of the hub. When I opened the hub two years later the hub was clean inside but there was a detached pawl spring (high-speed freewheel), I made another with some success from a strand of brake cable but it is better to buy another spring. (I have obtained another from a bike shop)

In conclusion, the gear hub needs oiling and you can not over oil it because the oil will come out of the larger bearing carrying water and dirt with it. The inside won't be bathed in oil consequently. Older hubs oiler port do not have a sealed cap so excess oil would also overflow out so keeping the transmission as light as possible by using enough but not an excessive amount of oil.

Sturmey-Archer AW variable gear hub made after 1989 with no oil port. Lubricating; (I have not carried out this maintenance procedure)

A thin grease is used and every moving part of the hub must be disassembled and all moving surfaces greased. The hub will not work if a thicker grease is used because the pawl springs are very light and the pawls will stick.

- There is a Sturmey-Archer grease that can be obtained from SJS cycles.

- Millers semi-fluid EP bearing grease is the correct product for hubs after 1989. It is identical to the Sturmey Archer product but a lot cheaper.

- Castrol Spheerol L/EP0 is also a thinner grease that is suitable.

Alternatively;

But if you've cleaned the hub out, you should put the hub back together and before you set the left-hand cone, squirt in some thin oil. Engine oil is fine, just a quick squirt is enough.

Use grease as normal in the OUTSIDE circular groove in the cone dust caps and a thin smear on each of the wheel bearings, and the freewheel bearings.

Condition of variable gear hubs;

In three cases of a variable gear hub being out of use for many years possibly a decade or more in each case, the pawls had not stuck but in a 4th case, a spring had broken.

- 1950 FW the wheel turned freely and three of the four gears worked there is a fault in the hub, cable and trigger design but the hub had been properly oiled with thin oil regularly when in use since new more than 25 years earlier. This hub had been oiled for its first 25 years with the wrong oil, 3-in-one, that had caused the fault after 30 years or so of a lot of use but the hub was otherwise clean inside.

- As if the hub were designed for a stiffer cable run. The cable is very tight in Bottom gear both the cable where it had rusted on the pully wheel and the indicator rod have broken in the past.

- Chose to set the cable to the indicator to get speeds 2,3,4. Or tighten the cable to get speeds 1,2,4. The much greater pull effort required to get bottom gear means that the cable assembly must not be too springy. If a pannier bag carry's much weight knocks the cable it will knock the hub out of N (3) gear. You may have just two good speeds 2 and 4.

- The trigger is not worn enough to explain the issue and the notches are precise, not worn to radiuses. I have seen a newer four-speed trigger with much more wear no doubt used with a newer type FW hub. Four-speed triggers are often replaced but I have not done that.

- It turns out that the section of cable with an outer sheath should be no more than 18" this forms tight curves on my drop-handlebar bike. Sturmey-Archer specifies this maximum length of the sheathed section of cable run The cable is of a less springiness construction. I am not convinced that this was necessary but I have reduced the cable sheath length by 10". I have added some tape to hold the cable in line with the trigger to reduce the change in cable length as the cable is pulled tight. Consequently, the cable radiuses do not change much with cornering.

- The correct Sturmey-Archer cables outer sheath is smaller in diameter but thicker square section spiral than brake cable and has a strong plastic outer that is less degraded by UV sunlight. The cut ends should be ground level such as with a pen knife sharpening carborundum stone to grind the cut ends of the outer spiral flat.

- This has improved the function and I now have 4 good speeds but the cable will have to be adjusted often. The maintenance work carried out for me on the hub has made its function better than it had been for a number of years plus the N gear does not click (not the freewheel tick) that had existed since the hub was new, and my father complained was a shame because it is the best gear. As this is a late, early-type FW the click in N probably was, a back of a fag packet, work-around as (undocumented modifications).

- Another solution which I am advised improves the reliability of the hub and makes gear change easier is to convert it to a two cable, five-speed hub. I have not seen carried out this modification to the hub;

- https://hadland.wordpress.com/2020/04/19/converting-the-sturmey-archer-fw-4-speed-hub-into-a-5-speed/

- No. 6 of a set of videos on the conversion If you don't have the suitable sun gear you will still have 4 speeds but with an easier cable pull but it won't be modified to an S5 hub and there will be an excessive strain on the second cable if you pedal in super-high gear;

- https://youtu.be/KJCPmj4I8CI Part 1 video (the early type FW before about 1950 should have the correct type sun gear, I believe),

- https://youtu.be/n3smEgvhf-M part 2 video,

- https://youtu.be/T96kiwY39i8 part 3 video,

- https://youtu.be/dwauZgc60os Part 4 video,

- https://youtu.be/cy7SdOjMFcE Part 5 video,

- https://youtu.be/HOTVluTo5cY Part 6 video explanation (also above),

- https://youtu.be/qNHM4mmXjMg Part 7 video changing the cogs,

- https://youtu.becChd-drYSmcc Part 8 video cables and levers on the bike.

- In conclusion, the FW is such a nice hub with gears spaced just right with N being the most efficient perfectly placed when you get to the top of a hill, level out, speed up and need a rest. Bottom gear is hard to get into though and on a hill by the time I have pulled the lever to B the bike has stopped moving. The hub along with a very good sports frame and very low friction thin oil lubrication is worth keeping and running.

- 1975 AW which oiled before using worked properly. Internally was in sound order but was full of a rusty oil mixture.

- 1985 AW gear change was difficult for some time but with plenty of oiling the operation of the hub came smooth and easy. There was a lot of sediment in this hub which flushed through eventually with plenty of oiling. On opening, one pawl spring was destroyed.

- 1997 AW worked properly when I started using the bike but after I had cycled 1KM speed 3 stopped working. The cable adjustment needed to be slackened to set the cable correctly and I have found the hub turns very freely and the gears change easily.

Thin-oil is spread well around the hub then leaves the hub by the bearings mostly the large planet carrier bearing then oil leaves the hub and falls onto the bicycle chain. Thicker oils or thin grease tend not to spread around the hub and leave the hub.

Modern engine or gear oil is designed to stick to surfaces and not run off even when a car engine is hot. Mineral lubricants don't deteriorate over time as they used to 50 years ago or more when all bearings were lubricated annually and engine oil changed twice a year or 3,000 miles.

Thank you to a number of people who have advised me in various Facebook bicycle groups.

Older non-AW type hubs

- Some of these have more than one lubrication point - FM, FC, AM and AC for example are more complicated and have two epicyclic gear assemblies.

Picture right; Broken old type indicator rod and toggle chain from an FW (or FG) variable gear hub. The indicator rod will fly out if you simply unscrew the toggle chain on the hub made up until about 1950. On such an older hub with an indicator rod, unscrew the indicator rod so that the toggle chain on the other side can slide out.

There is one spacer between the drive sprocket and the variable gear but the video above shows two spacers and it is important to put them back as they were found. The sprocket needed to be put back the other way like the video and another bike that I have. In conclusion, if this dynamo were to be used on another bike the location of the spacer or spacers would need to be reviewed.

I was able to test the function of the variable gear by screwing an old thread type thin 1.5mm spoke into the toggle chain place and see that the variable gear operates properly. The 3-speed Dynohub's gears have not been road-tested on a bicycle.

---------------------------------------------------------------------------------------------------------

Magnet keeper - if required;

You can push the keeper or another winding, as a keeper, in from one side and thereby push the existing winding out for inspection and cleaning. See TEST 4 below if you need to take this step which shows a procedure and measured outcome.

I have been told by one person who did not have a keeper and separated the magnets to clean it then put it back successfully. But do not do that, there is no easy way of re-magnetising the magnet.

-----------------------------------------------------

Testing the dynamo;

1. With the bike wheel off the ground so that it can be spun freely;

- GH 12 - I believe the circuit is two 6V filament lamps in series rated at 150 mA. Short one lamp to see if the other lamp illuminates then short the other lamp this will determine if there is a simple lamp failure.

- GH 8 - I believe the circuit is two 4V filament lamps in series rated at 250 mA. If the circuit is the same as the GH 12 then the test is the same.

- GH 6 - The circuit is two 6V filament lamps in parallel rated at 100mA and 200 mA. If one lamp fails then the other lamp will be supplied with too much current and fail. Therefore, turn the wheel slowly at first to see if one or both lamps illuminate.

- All hub types operate silently but for the ticking of the freewheel.

- Turn the shaft and notice the dynamo's detent force - which feels springy sort of lumpy and is very light. It does not matter which direction the wheel is rotated in. The magnet is magnetised.

- Short the dynamo output with a wire. Turn the shaft and notice the dynamo stronger magnet detent force - which feels springy lumpy but takes more effort. The magnet is magnetised and the windings are good so the dynamo is good

- If the force was no different as described the winding probably has a short circuit or the connection is an open circuit.

- Check the continuity with a battery and a lightbulb or a multimeter.

If there is doubt about the lamp and the dynamo circuits test the lamp circuit with a battery instead of the dynamo. Of cause, you can test with a multimeter rather than traditional methods but a multimeter in its time such as an AVO would cost more than a new bike in the 1930s. The current from a battery and lamp continuity tester connected to the dynamo will cause a small high voltage spark when you disconnect it is called back-EMF.

The moving iron test meter pictured right is probably 100 years old and had cotton covered wire with a small probe tip. It works AC or DC but the scale does not say which it is calibrated in. Notice that the body of the meter is live, I have not carried out any measurements with this meter. It would have been much less costly than a multimeter but it was not a cheap instrument.

---------------------------------------

The second tool re-magnetising the magnet;

This is the same process that happens with a computer hard disk. A high pulse of magnetism is applied to the hard iron material to magnetise it. Such a pulse will also switch a magnets polarity north and south poles. This is done with the dynamo fully maintained and assembled then briefly connecting a high voltage direct current power source with a circuit breaker or fuse and protection diode to the Dynohub output.

Providing that the mu-metal can carry this amount of magnetism without saturating - which is very likely because motors and generators are usually assembled then magnetised after assembly in this way.

There is a risk that the high voltage applied to the dynamo winding will cause the insulation to break down. The winding needs to be dry but the insulation may have deteriorated over time so applying a high voltage to the winding may cause it to fail.

I have not carried out this procedure at high voltage consequently but I have tried the procedure at a lower voltage inconclusively and have suggested a method below. It is most likely that the insulation will withstand high voltage if it is dry and has not disturbed but the very old enamel on the copper wire is brittle and flakes off if the wire is moved. Enamelled copper wire in anything made after about 1950-1960 is much better and retains flexibility.

AL-0030-02B S1 is closed briefly then opened to re-magnetise the dynamo. When S1 is closed the current starts to rise in the dynamo winding represented by L1, 5.5H (measured and calculated roughly) and R1, 5Ω (measured). D1 prevents the circuit from creating a high voltage (back EMF), arcing which will hurt you and damage the dynamo's insulation.

RED = Volts, GREEN = Amps. The Ground symbol shown is not earth but is a reference point for this SiMetrix simulation.

20A pulse shown is probably the current required to fully magnetise the dynamo (guessing based on patent detail above and the B-H curves below). It is necessary to re-magnetise the Dynohub with the lowest possible voltage because of the age of its insulation it needs to be clean and dry, but without causing undue heating due to the longer time required to attain a high enough current. Therefore just enough current be applied to magnetise the Dynohub. Expect the Dynohubs output to be a higher current than rated. These magnets have a wide tolerance in magnetic strength consequently the increase in the dynamo's output may vary. The winding current must be less than the fuse rating of the wire but I do not know what the thickness of the wire is?

Assume that thinned copper wire fuse rating is similar to enamelled copper wire used in the Dynohub;

Estimate;

Winding bobbin ID; 42mm, OD; 58mm, Width; 13mm = 18mm-5mm, Winding fill factor; 75%.

Cross-sectional Area; 156mm2 = (42-58) * 13mm * 75%

Mean length; 157mm = π * (42 + 58) / 2 [π × mean diameter]

Resistance of one turn of copper wire; 12.7uΩ,

Multiplier for; 628.5 = √(5Ω / 12.7E-6Ω),

Wire; 628.5 turns of 0.25mm2 = 156mm2 / 628.5, diameter; 0.5mm.

Length; 98674.5 = 628.5 * 157mm.

For a GH6 dynamo, a short pulse of current up to 20A probably won't cause the winding to break open-circuit.

Diagram right; AL-0030-01C but at 350Vdc, 20A is attained in 0.4 Seconds and less heating. But more of the self-heating occurs after the current is turned off (the area under the curve is larger). This can be reduced by fitting a ~10R power resistor or a surge suppressor in series with the diode.

Include a quick blow fuse in the circuit before the rectifier in case any part breaks down, for safety, may also save the Dynohub from damage. Progressively increasing the voltage or the fuse rating up to 5A or 10A (will break in 0.5 seconds at 3-4 times its rated current) until the dynamo's magnet has become stronger. It is likely that a suitable high-power bridge rectifier will be found in an old washing machine.

A rectified mains supply is more practical. The simulation AL-0030-03C (Right and Below) - the rectified AC component in the red supply voltage pulse. 230VAC with rectifier 0.7 Seconds to reach 20A.

The simulation is similar to the battery charger circuit below but operating from 230VAC with no transformer. A fuse - switch - circuit breaker - and a mains voltage high current bridge rectifier need to be added but the ammeter and capacitor are not included.

I HAVE NOT CARRIED OUT THIS PROCEDURE AT MAINS VOLTAGE AND I DO NOT INTEND TO. IT IS DANGEROUS EVEN THOUGH I RECOMMEND USING A CIRCUIT BREAKER TO LIMIT THE CURRENT QUICKLY SO PROTECT THE DYNAMO. I ALSO RECOMMEND AN EARTH LEAKAGE CIRCUIT BREAKER (ELCB OR RCD) FOR SAFETY.

I did not want to damage a good Dynohub.

Ensure that the armature can move freely the poles will then align ready for the pulse of current to re-magnetise. You can test the magnetism by turning the armature if it feels lumpier the strength of the magnet has been increased successfully. This detent force should be much higher if you short circuit the output to confirm that the winding is not a short circuit or open circuit as a consequence of re-magnetising the magnet.

It will be necessary to experiment to find out how much is just enough current so thereby minimise the risk of damaging the Dynohub?

It would be better to use a variable current power supply so that the magnetism can be steadily increased in steps of pulse, rest to cool, then test until the Dynohub produces the correct current. That is the magnet is used in the linear region in a similar way that sound is recorded on tape by a tape recorder. This is unlikely to be practical and the magnet will be magnetised to saturation and the Dynohubs output power will be higher than 300mA.

Alternatively use a car battery charger;

The car battery charger is connected to the dynamo, the dynamo shaft can move freely so that the magnet poles align when the pulse of power (magnetism) is applied.

The next step is as before switched on for one or two seconds then switch off. Take care to switch off quickly so that the dynamo winding does not heat up. Do not disconnect the dynamo whilst the power is switched on because a high voltage, called back-EMF, will be generated that will put the winding under stress unnecessarily. See diagram below;

AL-0031-02B The car battery charger has an internal rectifier diode so another diode is not required. Connect up then switch on for 10 seconds or so then turn off. The low or high charge switch setting and then adding the capacitor will progressively increase the current and therefore the resulting dynamo output after re-magnetisation.

It turns out that it takes a few seconds for the current to build up before the armature moves.

What happens; The armature (generator winding) of the dynamo (generator) will move and the magnet poles (field) and armature segments will align or re-align as the current and the magnetism increases.

Video - Car battery charger used to re-magnetise the dynohub.

Ensure that the dynamo can move freely so that the poles can align. A moving needle multimeter or a filament bulb (2.2V 470mA pictured) does a good job of measuring the function of the dynamos. Look at the colour of the light to gauge current. The old capacitors are similarly rated 30V to 63V 2,000uF to 5,600uF and the larger one is older.

A digital multimeter does work if you keep the hub turning steadily for a longer period and turn off the auto-range feature. A moving coil (needle) type multimeter works better giving a steadier reading. The bulb lights up white indicating that the current was 470mA as the light bulb is rated and works particularly well because current is drawn so the connections are good.

It would appear that although the magnet seems weak judging by how much mu-metal sticks to the magnet but this type of hard iron magnet was going out of fashion in the 1950s and TV manufactures were using stronger ceramic magnets which are black rather than silver. Holding the shaft in a vice - wrapping string around the housing and pulling voltage and current measurements are difficult to make.

I measured up to 400mA short circuit with a digital multimeter, although the dynamo is only rated at 300mA. The current may have risen to 480mA after re-magnetising. Measuring the open-circuit voltage with a moving needle multimeter was a little easier at up to 12V increased to 20V after re magnetising. Adding the capacitor to the circuit doubled the current in the dynamo winding but did not, as far as I can tell, increase the power output of the dynohub after a re-magnetising again.

Warning this method was too imprecise to be conclusive. But the method is correct even though the voltage was not high enough. Adding the capacitor doubled the current to show 50%, but testing the dynamo showed no further increase in the current output subsequently. This could be the dynamo is fully re-magnetised or not enough current was applied to change the amount of magnetism.

To properly test this procedure and voltages suggested the dynamo needs to be fully demagnetised. I could connect the winding to the mains 230V AC this should be adequate. But that is risky so I am not going to do that.

Tests 1; With the dynamo clamped by the shaft with a vice and string wrapped around the hub body then pulled;

Open circuit V, Short circuit I, 12V 6W Lamp

Slow; <10Vac, 440mA, <4V

Fast; 20Vac, 470mA ~6V

Very fast; 30Vac, 500mA, 8-10V

The dynamo's output is as originally expected nearly constant current regardless of speed and an open-circuit voltage proportional to the speed of rotation.

Repeating the point the measurement is very imprecise and would be greatly improved by fitting the dynamo to the wheel on a bicycle and turning the pedal at a steady speed for longer.

Test 2; Reverse the polarity of the magnet

- Connect up as above and pulse the power on/off so that the poles align*.*

- Reverse the polarity of the power supply.

- Clamp the dynohub stationery then power on/off.

- Un-clamp the dynohub so that it can move freely then power on/off.

- If the magnet polarity had changed the dynamo should not move but it did move to a new alignment.

- I also tried with a 20V DC power supply unsuccessfully.

The battery charger probably does not provide adequate power to reverse magnetise the dynamo but it has increased the magnetism of the dynohub. The circuit may be useful.

1. The magnet is not fully saturated and therefore a little more power could be obtained from the dynamo.

2. Because the magnet could not be reversed it is also likely that a dynamo that is completely demagnetised would not be re-magnetised without using a much higher voltage and current pulse?

Test 3; Demagnetise the dynamo so that magnetising the dynamo test can

be repeated.

- Connected a 35VAC to the dynamo - this was not adequate and the dynamo remained magnetised but the magnetism was reduced.

- The current output but showed the current was reduced to; 380-400mA after the demagnetising experiment. Then re-magnetising and increased to 400-440mA subsequently.

This test failed to demagnetise the magnet. I am not willing to use a higher voltage.

WARNING - Test 1 suggests that the dynamo's current output will be higher than initially rated, remain the same after three days, and are unlikely to diminish over time. The dynamo needs to be de-magnetised then re-magnetised but at a lower amount of magnetism. Alternatively left as it is with higher power output.

Test 4; Replacing the winding with the magnet keeper

Pushing the keeper in and whilst pressing the keeper into the magnet to ensure the magnet has minimal gaps and the magnet path is as good as possible.

Winding removed - the fingers of the iron are tapered at the furthest tips of the soft iron fingers.

- The keeper has been made long enough to be used on larger diameter GH8 or GH12 dynamos.

- Once the Dynohub was re-assembled the power output proved to be uncompromised by having been disassembled.

- Testing the output voltage peaked at 30Vac as before and the short circuit current varied between 370mA to 420mA slow to fast.

- The tapered fingers of the coil iron as the magnetic flux lessens would not be done to save materials cost, unlike a modern design. I can not see is not part of some voltage regulation strategy mentioned in the patent. Any power saving would be trivial due to magnetising loss is reduced.

The assembly did not need cleaning but I did rub the parts with a little grease. I am advised that the gaps between the magnet poles can be cleaned with a pipe cleaner.

Test 5 - repeat tests after at least 1 month since re-magnetising the dynamo;

Slow; Vac open >17V (analogue), Iac 370mA (digital)

Fast; Vac open >25V (analogue), Iac 390mA (digital)

The digital multimeter, as before, gave less reliable readings. I also measure the average current with the moving needle multimeter and a bridge rectifier and this gave a consistent 300mA fast or slow. The true value; 330mA (RMS) the meter is 40 years old out of calibration and the needle did not have a long enough period of current flow to settle at a final value.

Ipk = Iav / 0.637

Irms = Ipk x 0.707

Irms = Iav x 0.707/0.637

_330mA _= 300 x 1.11 - Warning although the analogue multimeter gives consistent results it most certainly is under reading and the current is higher.

Using a light bulb 2.2V 470mA and 12V 6W I perceive that the dynamo power has diminished a little. The multimeters tests suggest reduced by 5-10%. The moving needle multimeter did not fully settle because I was not able to keep the dynamo turning long enough but it gives the most consistent results.

Conclusion - re-magnetising and electrical;

The magnet material has a tolerance but evidently, the magnet was not originally magnetised to its saturation but even so, still has very good retention of magnetism. With readily available fixed voltage second-hand equipment power supplies it is only possible to re-magnetise a dynamo to give maximum output of about 400mA AC in this case.

These tests have not proven that the current used to re-magnetise the magnet in these experiments was high enough to do that. I did not want to demagnetise the Dynohub that I have to test this though.

My guess is that a fixed current is used to partially magnetize the magnet to achieve a 300mA dynamo output current. The correct current is likely found and set for each batch of magnets.

The point about magnetising to saturation is so that the magnet would be as strong as possible but the material used has a broad tolerance. This tolerance would have made the output power vary between batches of Dynohubs made. Much more power is required to magnetise the magnet to saturation, but the effort required to demagnetise the magnet is also much more.

Older style block power supplies have very loose regulation, so it should be possible to wire a number in parallel to achieve the desired current rating. Because of their loose regulation, the current would be shared fairly equally.

Pictured right; Old heavy transformer type block power supplies. These range from 12V, 1A to 1.5A so two in parallel may be enough to re-magnetise a dynamo. Four in parallel, in series with another four in parallel increase the amount of re-magnetising current. That is 12V, 2-3A or 24V 4-6A. Ensure that all are plugged into a gang of sockets then the mains supply to the gang of sockets is switched on briefly then off. That is so that all the power supplies are switched on and off together.

---------------------------------------------------------------------------------------

Rectifier regulator and LED lighting;

You can scavenge for rectifier diodes from an old PC power supply on the low voltage side diodes are usually more efficient lower voltage drop Schottky types. Schottky diodes have a low reverse voltage rating of 20V or higher but some newer types are rated at over 100V this means that a low reverse voltage rectifier could be destroyed by the Dynohub at speed if the lamp units are disconnected.

It is very likely that many working LEDs and optics could be recovered from a broken car head, side and tail light units - generally if one LED fails, open circuit, then the whole unit turns off and a dashboard warning is shown as a legal requirement in order to avoid ambiguity. These units operate from 5V to 24V and will withstand 60V. LEDs operate efficiently over a wide current range but their colour may change outside the road-legal red, amber, or white. The intensity is of each colour is also defined law as is the intensity of the stop or tail light functions.

The red LED colour is controlled by the current fixed and the intensity stop or tail light function is changed by pulse width modulation. PWM may operate at 100Hz, on at 100% for the stop function or for 10% of the period, for the tail light function. Some LED types are specified to retain their colour over a wide current range and some batches of LEDs colour are stable over a range of current anyway.

Dynamometer tests (http://minisystem.blogspot.com/2011/11/) on a GH6 dynamo show, the Dynohub's output reached 6V 300mA at 30KPH below this speed, that blog's LED lighting drew progressively less current. For a 26' wheel that covers about 2M per revolution the output frequency would be 83Hz which would not produce any noticeable flicker whereas 50Hz is noticeable.

- Therefore half-wave rectifier circuits (1) and 2 but without capacitors will noticeably flicker at 15KPH (41Hz).

- The full-wave rectifier circuit (3 and 4) without the capacitors fitted may not noticeably flicker at 7KPH (41Hz). The time that the rectified AC cycle is not carrying current is much shorter.

Capacitor values are estimated based on simulation for <30% current ripple in the LED at a frequency of 20Hz. Arbitrary White LED was chosen and scaled for RED LED in the LTspice simulation AL-0037-???.

1) 100% current; Total = 5.7V = (White LED 4V) + (Red LED 1.7V).

The LEDs will alternately illuminate with the generator's cycle of alternating current output. At low speed, all LEDs turn off as the voltage transitions through 0V. Together this may not look acceptable to oncoming traffic or pedestrians.

2) 50% current, lowest voltage drop;

- Total = 4.4V (white) = (Diode 0.4V) + (White LED 4V) and

- Total = 2.1V (red) = (Diode 0.4V) + (Red LED 1.7V).

Minimum operating voltage; >4.4V

3) 100% current; Total 6.5V = (Diodes 0.8V = 2 x 0.4V) + (White LED 4V) + (Red LED 1.7V).

The reservoir capacitors shown are much less necessary than they would be if half-wave rectification were used.

4) 100% lower Voltage parallel lights;

- White; Total 5V = (Diodes 0.8V = 2 x 0.4V) + (White LED 4.2V),

- Red; Total 4.2V = (Diodes 0.8V = 2 x 0.4V) + (Red LED 1.7V x 2).

- Therefore the input voltage should be at least; >5V

- The white LED circuit is provided with 3.5 x the RED led circuits current.

- The two transistors should be matched and mounted together, such as using an IC type multi-transistor array. Some candidate parts; MMDTA06, MMDT2222A-7-F, DSS4160DS-7, DSS4160FDB-7, ZDT694.

This circuit may overpower if the RED LED and white LED circuits are too imbalanced in voltage.

Circuit 2, 3 and 4 if one lamp or both lamps are disconnected, the rectifiers will need to withstand at least 30V reverse voltage. A Schottky rectifier rated at 50V or higher is required.

Simple Lighting systems suggestions (AL-0035-01D)

The LEDs may flicker a little but I have shown various mitigation measures and I also suggest using scavenged parts.

No allowance has been made for temperature and component tolerance (worse case design).

The RED LEDs will be much too bright in circuits 1, 2 and 3 without adding optical filtering.

DC-DC converters & LED drivers;

A variable voltage or LED driver from 5V input evaluation boards- I have not evaluated any of these. PAM2841SR boost LED driver 2.7V to 5V in. There is an evaluation board for this IC. Note that the input voltage must be lower than the LEDs (in series) voltage drop so that the IC can regulate the current.

There are many other manufactures and types such as; PAM2803, ZXLD1321

that operates 1V to 3.3V at least.

ST buck-boost type use with circuit 4;

I DO NOT RECOMMEND THIS SOLUTION BECAUSE I HAVE NO RECOMMENDATION FOR

CALIBRATING THE LAMPS LIGHT INTENSITY AND PATTERN TO MEET ROAD STANDARDS

FOR BICYCLES.

Combining the voltage pre-regulator above and then using a cheaper semi-regulated function block should be cheaper than using the evaluation boards above.

Picture right; Surface mount LEDs - A Printed Circuit Board can be made with a footprint pattern like the reverse side but as if you were looking through the parts from the top. Design the board with components on one side only. Place very small dots of solder paste onto the pads (it should look as if you have not got enough solder paste on the pads). Then place the LEDs and other parts on the PCB you don't need to fit all parts at the same time or be overly careful to align them properly surface tension will cause the parts to pull to align (or miss-align). Place the circuit board on a suitably pre-heated hotplate to solder all the parts. Using tweezers to correct any parts that go out of alignment or tombstone (stand up). Use pliers to remove the

board from the heat. The board will go brown because it has been overheated and for too long but your circuit will function fine - heating and cooling need to be done quickly without jarring the PCB.

No PCB needs to be designed and ordered if you unsolder the parts off of an old circuit board, cut the tracks as necessary and place your desired circuit and wires this works well. Alternatively, you can buy some stripboard or Vero board and do a similar thing with that but you probably will need to reduce the power rating of some parts such as LEDs in order to prevent them from overheating due to the lack of solder pad, copper area for heat-sinking.

Picture right - Stipboard or Veroboard can be used for prototyping of finished one-off design. The prototype may be a mains power supply with switch-mode Lead-acid battery charging? This type of prototyping can be good to see how a function works but usually, the function does not work so well unless the design is not demanding.

Alternative - Bicycle dynamo light and battery manager --- See Addendum at the bottom of the page and also see; Electronics-design-project-bicycle

----------------------------

Links and references;

Tests of modern Hub dynamo efficiency's;

A method of overhauling the dyno-hub that I used;

Sturmey-Archer - Dynohub history

GH12 (1936-38) - Dynohub, 12V, 2.7W and 3W

GH8 (1938-41) - Dynohub, 8V, 1.2W

GH6, Dynohub, AG and FG variable gear hub-dynamos. 6V, 2W and 1.8W

Tony Hadland - How to repair old Sturmey-Archer hubs

Ratios of various gear hubs

At a constant speed, the power output is less when simply rectified but thè voltage and current take allowed to vary maximum power transfer at,

Note that the GH6 front wheel fitted type hub dynamo bearing adjustment is

carried out from the non-dynamo side. Unlike the AG variable gear dyno-hub.

Magnet and magnetic material characteristic B-H curve https://www.quora.com/What-is-a-magnetization-curve B = Magnetic force and H = Amp turns the current in the wire and the number of turns of wire if there were no losses in the magnetic circuit. https://www.coolmagnetman.com/magfund07.htm

AlNiCo Magnet (aluminium, nickel, cobalt) material B-H curve shows the magnet can be magnetised at a lower degree of magnetism.

At very high temperatures, the material will de-magnetise called the curie point. When the material cools again the magnetism can return. This way is not used to magnetise the magnet. The magnetisation is usually done after assembly with the material cold with a strong pulse electromagnetic field;

History of modern magnetic material;

Another bicycle dynamo project I am unsure about the data and the project was not completed but there is a useful dynamometer graph for a Dynohub;

I do not know anything about this company but they do offer a re-magnetising service. They do magnetos which is what a Dynohub is but they are busy and it would probably be easier and cheaper to swap the inside from one hub to another. The Magneto Guys - Vintage, Veteran, Classic Magneto and Dynamo Repairs; https://www.themagnetoguys.co.uk/

---------------------------------------------------------------------------------

Appendix; Motors that will also generate power;

- 1970's Impex 350mA, 5V/winding (4), 48 step stepper motor. 8 wires.

- 1950s Induction motor (variable reluctance motor) - is not magnetised but will magnetise when connected to an AC power and spinning. The capacitor provides a phase-shifted supply and sets the motor direction. When spun a little faster than synchronising speed, this motor will become a generator and put power back into the supply.

If disconnected the motor stops generating power safely. But if capacitors are connected across the windings and the rotor has remnant magnetism some of these motors will build up magnetism and start to generate power when spinning.

- Permanent magnet brush motor - will produce direct current if spun.

- 1980's Astrosyn stepper motor; 24-step, 16V, 80ohms (200mA)/winding (4) - this has a much more powerful magnet than the 1970s Impex motor and is a more powerful motor it is smaller.

- This motor would make a good bicycle bottle generator.

- Central heating timer permanent magnet motor - this is like the dynamo in construction but turned inside out.

- Hard disk stepper motor 8 pole - this will also generate but the voltage is so low that it would have no use.

Picture right of a high number of steps, stepper motor. The shaft is mild steel and can bend easily so the coupling to the shaft must be flexible. The construction is different from the dynamo with the two rotors are North and South poles of a central magnet so that the teeth then present alternate poles as the rotor turns.

The motor is assembled then the magnet is magnetised by a pulse from a high voltage source. This type of construction is used from 24 up to 500 step hybrid stepper motors.

The motor is assembled then the magnet is magnetised by a pulse from a high voltage source. This type of construction is used from 24 up to 500 step hybrid stepper motors.

The generator

A hub generator would be improved if it were a two-phase (4-wire) or three-phase (3-wire) the extra wiring cost is mitigated by integrating the rectifier, overvoltage protection and power management plus speed output into the generator. But the single-phase generator was the most cost-effective and a good solution in the 1930s to the 1990s that has set the standard for voltage output.

3-phase only requires one extra wire. The 3 wires fed to a full-wave rectifier would cause a ripple in an LED would only be 15% (https://electronicscoach.com/3-phase-rectifier.html) that would not be discernable to the eye.

All losses may be reduced if a design based on a good quality stepper motor turn inside out with say three, four or a multiple of that central windings plus a flexible coupled no side-thrust carrying bearings so that the air gap can be reduced and saving copper or copper losses all from an established motor may have improved on. See pictures of a motor above these that can have a large hollow shaft so possibly be fitted inside a large bicycle hub over the shaft? Such a design can be drawn up in a mechanical CAD and with the correct modelling add-ons accurately modelled.

-----------------------------------------------------------------------------------------------------------------------------

Appendix; Bicycle dynamo lights and battery manager;

Microcontroller-based bicycle dynamo light and battery manager with a speedometer. Design idea and exercise with STM32 microcontroller. With interface by USB cable for speedometer display on a tablet for example.

- The Dynohub should output up to 20V when the bike is ridden fast I understand. That is up to 7W.

- Manage battery charging.

- A tilt sensor is used to reduce the power taken from the dynamo using parameters set by the cyclist such as a tablet computer connected.

More electronics design variants in detail see;

This would be a costly design to develop and a high value to sell.

No recommendation but here is a link to a generator-powered bicycle light. A reservoir capacitor can be seen inside to smooth fluctuations but I do not know how well it shares power if two lights are fitted?;

----------------------------------------------------------

Appendix; Experimental Bicycle bottle generator lighting

Astrosyn stepper motor; 24-step, 16V, 80ohms (200mA)/winding (4) - in experiments produces 4x >35Vac at 25mAac. The motor makes a good bicycle bottle generator although the sleeve bearings will wear out sooner than a ball bearing type motor. By nature of its cheaper construction, having a longer magnetic path and less segmentation, be less efficient.

- Running, say, four times two strings anti-parallel of 7 + 4 LEDs in series. Total 88 LEDs, would be the most efficient option. {Picture above but with all blocks of LEDs fitted}.

- Full-wave rectifier with or without the centre tap running two 11 LEDs in series. Total 22 LEDs, uses less wiring and has redundancy. {Picture right but with all blocks of LEDs fitted}.

X If the centre tap connection is used half the number of LEDs can be fitted at double the current thereby increasing losses due to winding resistance. The centre tap can also be

used to provide parallel redundancy in case an LED becomes open-circuit.

Experimental home-made bottle generator evaluation;

Astrosyn 1788-h269, 24-step, 4-phase (6-wire) 16V 80R/phase stepper motor. ~14mm gearwheel, Body ~42x22mm.

Output of one phase, short circuit; 60mAac, open circuit; >40Vac moving the pedal at a 4 seconds revolution speed-H(4). Wheel Circumference 2M (26"), ~2KM/hour = 2M * 3,600 / 4 seconds. ~6,000RPM (2.4KHz).

Power out possible; 5W = 40V * 60mA * 2. Copper loss; 0.58W = 60mA^2 * 80R * 2.

Copper loss, wire 2-phase; 0.29W = 30mA^2 * 160R * 2.

Power output with 1.5K ohm resistors across each of two phases, 2 phase configuration, the maximum voltage should be 45Vac (30mA * 1K5 ohms) expected but using a moving coil meter gave 35Vac and 37Vac with one winding disconnected was measured. The output reduces to; 23mAac = 35Vac / 1,500R, a 22% loss or reduction in current from the generator. [It is possible that eddy current losses are becoming significant hence the reduction in current]

Note this high gearing would make pedalling an effort and would produce unnecessarily high power. But reducing the gearing by a factor of 5 by fitting a 70mm wheel might make the added resistance feel modest?

0' is; V=1.4*Vrms, I=1.4*Irms,45' is; V=Vrms, l=2*Irms.

There is no power factor correction and less than optimum power is taken between 0' 45' 90' 180' 270'. But with a simple reservoir capacitor would output <2/3rds of the possible power. Roughly calculating for 5V or 6V out, buck SMP ICs;

- L7987L st.com; 4.2W = 55V x 1.7 x 2 x 23mA,

- LMR36510 ti.com; 4.6W = 60V x 1.7 x 2 x 23mA

- LMR36506 ti.com; 3W at 5V out.

A low power mains voltage power supply IC such as a mains to USB or phone charger probably could be adapted to start at lower voltage with the addition of current limiting taken from AL-0038-02 the ic use could be similar too; TEA1723 nxp.com would take half the available power 20mA and require >20V to startup.

--------------------------------------------------------------------------------------------

Final note;

I use spell checkers, grammar checkers and the web browser to check the spelling. Grammar checkers vary in usefulness Grammatic 5 was very good over 30 years ago and Grammarly is a good one just now. I use the free version Grammarly it works on many but not all combinations of web browsers and wiki websites; https://www.grammarly.com/ My grammar and spelling so readability has improved but creating and refining a blog is very a slow process. I similarly find embedded programming a chore moving from assembler to writing in C and using pclint (lint tools) helped but I have stopped doing that over a decade ago.

IF A=B THEN /* Is bad programming because is cluttered, ambiguous and wrong in C */

if (A == B)

; /* condition true but lint would give fewer warning */

else

A = B;