PT100 Temperature sensor.

- NTC Thermistors can be programmed with a series resistor to be roughly linear over a 40 °C temperature range.

- Two thermistor-type temperature sensors are roughly linear over a 100 °C temperature range but have a wobbly error graph.

- Semiconductor-type temperature sensors, such as IC types such as AD590, work well, and would benefit from a 100nF capacitor for reducing electrical interference. Works over and is linear over -55 to 150 °C.

Component selection; Sensors;

| ||

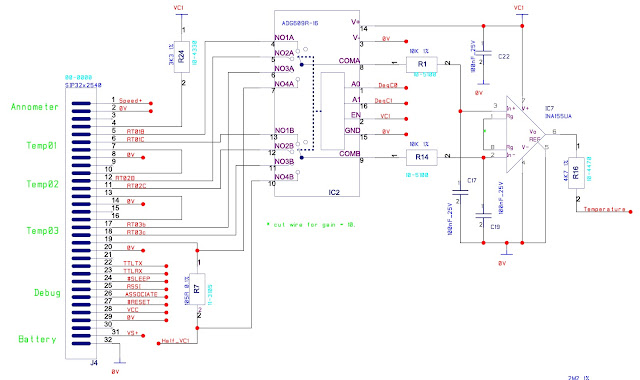

| AL-0016-01B The temperature measurement section of the circuit. Created with CADSTAR 16.0 Express. This first draft of the circuit won't work; the instrumentation amplifiers' reference input should be at least 0.8V above 0V or Vdd-0.8V. Resistance measurement is scaled by the resistance of the PT100 + R7 + R10. The calculation is circular, where the answer is required to do the calculation. If a typical temperature value of, say, 105 ohms is used, then an approximation will be found. In a continually running system, the next time the temperature is measured using the previous approximation of the measurement will be accurate. |

1. Change the Instrumentation amplifier to a INA155UA; this will work with 0V input at its Ref input, so the output will have a bigger voltage swing to improve the A/D resolution. In addition, its gain accuracy is better at 0.1%, but its offset is bigger. This solution should work if a lower x10 gain is selected and a higher resistor chain current, so that larger signals are used. In this case R10 can be replaced with a second PT100 temperature probe.

I did not understand Figure 6 in the AD8293 data sheet. It turns out that the pink area represents the lowest supply voltage operation at 2.7V, and the blue area, including the outer pink border, is for 5V operation. Here is my question on what Figure 6 means answered2. Change R10 to a precision resistor, and use it as a single point of scale factor calibration. R7 becomes not part of the calibration system and a general-purpose resistor would suffice.

CS5531, CS5532, CS5533 or CS5534, for example, is easy to use, more accurate and just requires the series resistor chain. It includes up to a 4-channel multiplexer fed to a single A/D. You don't need to use the Programmable Gain Amplifier, which, in any case, would have required a calibration cycle. So one of these could be used with one or four temperature probes and one precision reference resistor connected to the reference input, thereby also making the measurement immune to low-frequency common-mode electrical noise. The calibration selection of the IC serves no purpose; the IC is accurate from turn-on.

The opinion of sales representatives and other engineers is that the significant patents from about 1990 expired long ago, and all manufacturers of Delta-Sigma or Sigma-Delta type A/D converters should now be equally easy to use and similarly without the 100uV noise spikes that some of them suffer with.

I have used this with 0.01% accurate resistors as part of the calibration system, which gives a potential temperature accuracy of 0.05 °C, but it is not possible to trace temperature calibration to this accuracy. Each PT100 was soldered to a PCB along with connector, an I2C bus EEPROM which held a calibration constant for that temperature probe. It is often the case that instruments resolve confidently to a much higher accuracy than the calibration can be traced by a national standard to.

2. INA155UA Ref input works at mid supply, or if the inputs are near one power supply, the Ref input should be closer to that power rail. That gives this amplifier a bigger output range in these circuits, which is beneficial, spreading the signal over more of the wireless module's A/D input range.

Both amplifiers give better results when multiplexed and chopper-stabilised. It turns out that chopper stabilisation is not required, but multiplexing with a precision resistor in the resistor chain as one of the channels as part of a self-calibration system is a good strategy.

- If the Ref input and the resistor chain are switched, 0V and Vdd give two sample points per cycle of the A to D, so there should be at least 50% better accuracy by averaging. Any contact junction voltage offsets are eliminated, but switching noise and cross-coupling of synchronous signals would be introduced unless good care with screening and PCB layout is taken. See circuit 3.

A temperature accuracy of, say, 2 °C would have been good enough to proceed with the design.

Self-heating of the Pt100

2. Circuit corrections and improvements;

- The output voltage range is 1/3rd to 3/3rds Vc. 2.2V.

- Maximum ohms (range 144R) from the spreadsheet.

- Sensitivity ~6mV = 0.385R * 2.2V/144R, per 1'C

- Therefore, the accuracy of ~11mV corresponds to 2'C accuracy.

- But only part of the range is used; ~0.5'C = 2'C * 15 ohms / 144 ohms with single-scaling-point calibration system.

- Cycle through all four channels.

Allow a settling time, then take three readings for each channel so that mode averaging can be applied, that is, drop the highest and the lowest readings.

- Optionally, the mode-averaged measurements can be summed (which amounts to averaging) to further reduce the noise. The square root of the number of samples, if there is noise and the noise distribution is normal and of a reasonable amplitude at best, can increase in resolution 10X for 100 readings.

- Note that the successive approximation A/D on the wireless module must have a well-filtered input, or else high-frequency noise will introduce big errors.

- For each channel, do the sum; Temperature n = (105 * Channel n / Channel 4 {calibrator} - 100) * 0.385.

3. Chopper stabilised temperature measurement

The instrument amplifier chosen has a very small footprint. Even though I have hand-soldered this package but it would be better to use INA155 with the larger SO-8 footprint. Using two reference resistors was another option evaluated, one of those being 10R 1% (as a near-zero reference point) and the other 130R 0.1% (span reference point). This is approximately the solution I first used before.

- INA155 settles in 15uS to 0.01%. The cycle is the four mux channels twice is 8.

- Time constant of the final RC formed by the analogue mux and 10nF. 10uS = 1K * 10nF, and a rule of thumb given at college was that the circuit will settle in 5 time constants.

- If the voltage steps are, say, 10x bigger than the temperature signal, the time constant is 10uS + 15uS, and we need 10 time constants to get to 0.01%. Use 250uS settling and 8 steps per cycle is 2mS.

- That is, 2mS is a chopper rate of 500Hz maximum.

- AD8293 G80 with the recommended compensation 1.3nF and output filter 39nF, settling time to 0.01% is 2.4mS.

- 8 cycles is a maximum chop rate of 52Hz.

- Ref input can not be chopped rail to rail, but only about +-0.5V (2.7V Vdd minimum) or held at a minimum supply.

Chopping frequency;

- Ideally, a high frequency should be used; 500Hz is possible.

- A sub-multiple of 50 and 60Hz is 10Hz.

The last option is to chop at the main frequency of the country, 50Hz or 60Hz. In a vintage instrument (Polarimeter P70-4) that used mains frequency, this works very well until the synchronous motor's bearing wears, the motor slows slightly, resulting in a low-frequency beat with mains frequency, and the user sees a flickering

reading

.

The last option is to chop at the main frequency of the country, 50Hz or 60Hz. In a vintage instrument (Polarimeter P70-4) that used mains frequency, this works very well until the synchronous motor's bearing wears, the motor slows slightly, resulting in a low-frequency beat with mains frequency, and the user sees a flickering

reading

.

- The software should cycle through all channels, switch polarity and cycle through all channels again. A variable settling time is required depending on the voltage change between each step of the cycle, or a larger settling time be used.

For each channel switch, allow a settling time, then take three readings so that mode averaging can be applied, that is, drop the highest and the lowest readings.

Each channel is summed with the polarity switched readings subtracted from the positive polarity readings, so that the offset error is eliminated.

A number of cycles should be summed for better noise reduction and resolution improvement.

If software were running within the XBee wireless module, then local chopper stabilisation could be run with better timing than if run over the wireless connection. In that case, running chopper stabilisation is an unnecessary complication, and a higher frequency chopping is hardly possible.

--------------------------------------

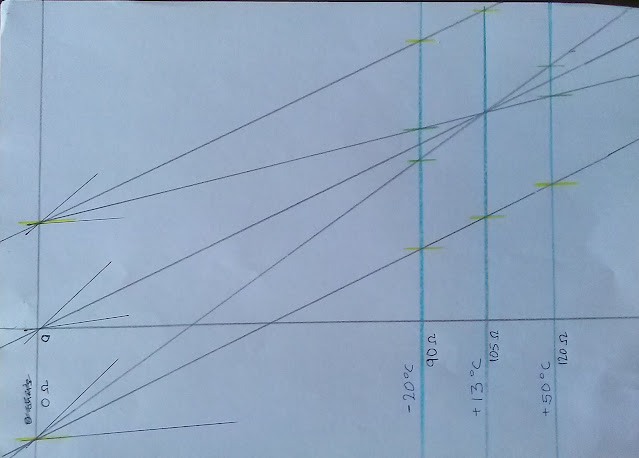

The temperature range uses a small part of the resistance range and an even smaller part of the total resistance of the resistance chain. I could not make up my mind how much this using a small part of the total resistance improved the accuracy, so I drew a picture. This made what would occur and what would not happen clearer, and I drew many versions of this graph before this one below.

It turns out that the total resistance chain is only relevant to how big the signal is to the amplifier, and the smaller the signal, and higher the gain, the system will have a poorer noise margin. On the other hand, the higher gain AD8293 has more low-pass filtering integrated.

The three diagonal Pencil lines are the ideal and offset error lines due to amplifier offset.

The Blue Biro lines that peter out are the amplifier gain and offset errors.

Blue Biro lines would be the significant errors if Circuit 1 were developed. From the spreadsheet INA155 with the gain set to 10 option and the measurement chain resistance of ~720 ohms is promising. In that case R10 becomes a second temperature channel.

Blue Biro lines emanating from the origin 0 are relevant to the chopper stabilised Circuit 3 in that case, though the resistance and gain accuracy using INA155 is much better and the required accuracy would be met.

Blue Biro lines are not relevant errors in Circuits 2 and 4 due to the single scaling point calibration system.

The Pencil lines intersecting with the 105-ohm calibration point show the accuracy improvement brought about by this single scaling point correction strategy (circuits 2 and 4).

- The Yellow pencil marks show the offset error without the calibration. This would have been the biggest error in circuit 3 that uses INA155 with a gain of 50. Improved using the gain option of 10.

- The Green pencil marks are the new improved by calibrated errors because of the smaller working resistance range -20 to +50 °C (92R to 120R).

4. Less input filtered INA155UA instrumentation amplifier solution;

AL-0016-04E CADSTAR 16, Less interference filtered INA155, but to mitigate the input is centred at mid supply.

An engineer can apply worst-case design tolerance and, by using a statistical approach, ensure that most products, when assembled, will work. That is close to how raw material and measured parameters come from nature and are first processed for use! But supplied components are made and specified, precisely and consistently, with all components meeting their tolerance specifications. This is how electronics have changed since 1980.

Solving complex resistor networks by trying standard value components in your equations and seeing. But first, do some maths. I do not solve using Maxwell's circulating currents and Superposition, but rationalise to simpler Norton's current source or Thevenin's voltage source equivalents. But to come back to the first point, a resistor network needs to be solved to use standard value resistors and satisfactorily meet the design tolerances. That tolerance is met by summing squares (of the errors), and this is called least squares. In a basic program written that loops until a good fit is found, some BASIC let you stop, edit it, then continue. I have done this, and it is powerful, but it is rarely necessary because simple circuits are mostly adequate to get usable data into a microprocessor, and then the arithmetic is carried out in that microprocessor precisely.

Summing up;

It is now possible to buy close-tolerance components cheaply, and these do not have a traditional normal tolerance distribution, but virtually all of them will work within tolerance. That is modern design work is now simpler; the part manufacturer has taken most of the design work out of your job. But the art of low susceptibility to electrical interference and understanding RF is important.

Summing up;

The PCB is more developed, and some other aspects have become clearer while working on the circuit. So the designer should go back repeatedly and improve the design until a satisfactory solution is found. For example the temperature range could be increased and the accuracy reduced.

Conclusion

No comments:

Post a Comment